920-726-4526

In the rapidly evolving landscape of modern manufacturing, the importance of precision and efficiency cannot be overstated. At the forefront of this transformation is the Vertical Milling Machine, a tool that has redefined machining processes and enhanced production capabilities across various industries. Unlike traditional machinery, the Vertical Milling Machine offers exceptional accuracy and versatility, allowing manufacturers to create complex parts with intricate designs. This technology not only streamlines operations but also reduces material waste and turnaround times, providing a competitive edge in the marketplace. As companies continue to seek ways to innovate and optimize their workflows, understanding the role of Vertical Milling Machines becomes crucial in unlocking the potential for enhanced manufacturing precision and productivity. Through this exploration, we delve into the why and how these machines are revolutionizing manufacturing processes today.

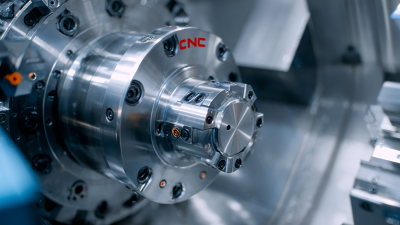

The evolution of vertical milling machines has been a cornerstone in modern manufacturing, primarily due to their unparalleled versatility and precision. Over the years, these machines have transitioned from manual operation to advanced computer numerical control (CNC) systems, allowing for more intricate designs and higher production speeds. The recent surge in the CNC vertical machining center market highlights this trend, with projections indicating significant growth driven by the increasing demand for automation and intelligent manufacturing solutions.

As industries embrace digital technologies, vertical milling machines are becoming more efficient and adaptable, integrating AI to optimize performance. This transformation is reflected in the broader milling machine market, expected to experience substantial growth as manufacturers seek smart automation and precision tools to enhance productivity. The continuous development of these machines signifies a pivotal shift in manufacturing processes, facilitating not only improved efficiencies but also a response to global competitive pressures, thus revolutionizing how products are designed and manufactured in today’s industrial landscape.

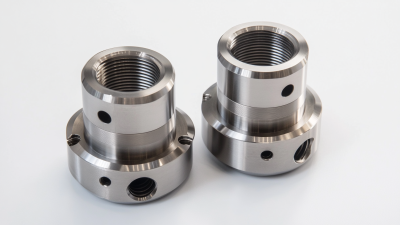

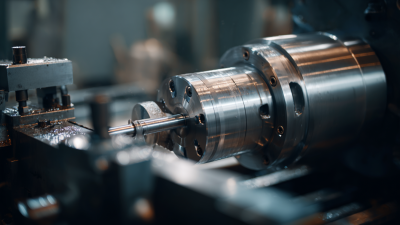

Vertical milling machines have transformed the landscape of modern manufacturing by providing precision and versatility. At the core of their functionality lies a rotating cutting tool that moves vertically along the material being machined. This axis of movement allows for intricate detailing, as the cutter can produce complex shapes and fine finishes that are essential in high-tech industries. The stability of vertical milling machines, combined with their adjustable table, enables manufacturers to work on a variety of materials, enhancing production efficiency.

Vertical milling machines have transformed the landscape of modern manufacturing by providing precision and versatility. At the core of their functionality lies a rotating cutting tool that moves vertically along the material being machined. This axis of movement allows for intricate detailing, as the cutter can produce complex shapes and fine finishes that are essential in high-tech industries. The stability of vertical milling machines, combined with their adjustable table, enables manufacturers to work on a variety of materials, enhancing production efficiency.

Understanding the mechanics of vertical milling machines reveals the intricacies involved in their operation. The machine’s spindle, which holds the cutting tool, can be adjusted for different depths of cut, allowing for a customized approach to each project. Additionally, operators can manipulate the workpiece’s position horizontally and vertically through the machine's table, further extending the range of possible applications. This adaptability not only streamlines the manufacturing process but also reduces material waste, making vertical milling machines a cornerstone of precision engineering in today’s manufacturing environment.

Vertical milling machines have transformed modern manufacturing processes by offering precision and efficiency that traditional methods often cannot match. According to a recent report by the Manufacturers’ Alliance for Productivity and Innovation, vertical milling contributes to a 20-30% increase in productivity for various machining operations. This boost is primarily due to the machine's capability to achieve tight tolerances and fine finishes, which are essential in industries like aerospace and automotive.

One of the key advantages of vertical milling machines is their versatility. These machines can handle a wide range of materials and complex geometries, which allows manufacturers to consolidate processes and reduce setup times. A study conducted by the National Institute of Standards and Technology shows that companies implementing vertical milling technology have seen a reduction in waste by up to 15%, leading to cost savings and enhanced sustainability. As businesses continue to seek competitive edges, the transition from traditional milling methods to vertical milling is becoming an essential strategy for operational excellence.

The applications of vertical milling machines span a wide range of industries, fundamentally transforming manufacturing processes through enhanced precision and efficiency. These machines are pivotal in sectors such as automotive, aerospace, and medical, where the demand for high-accuracy components is paramount. By utilizing vertical milling machines, manufacturers can achieve intricate designs, reduce waste, and improve overall production timelines. This adaptability makes them essential tools in environments where precision is non-negotiable.

Moreover, the integration of digital manufacturing technologies with vertical milling has further elevated their capabilities. Advanced CNC (Computer Numerical Control) features enable real-time adjustments and monitoring, facilitating a level of customization that was previously unattainable. As industries continue to evolve, the role of vertical milling machines in streamlining operations and meeting the rigorous demands of modern production challenges cannot be overstated. Their growing prevalence signals a shift towards more efficient, precision-oriented manufacturing practices across various fields.

The rapid evolution of vertical milling machines heralds a new era in manufacturing, driven by significant innovations and technological advancements. As manufacturers increasingly prioritize efficiency and precision, the adoption of Vertical Machining Centers (VMCs) has surged. According to a report by Research and Markets, the global vertical milling machine market is projected to grow at a CAGR of 6.5% from 2022 to 2028, fueled by the rising demand for machining precision components in industries such as aerospace, automotive, and medical devices.

One of the standout advancements in vertical milling technology is the integration of automation and smart manufacturing principles. The incorporation of Industry 4.0 technologies, such as IoT-enabled machines, has transformed traditional milling processes. This has led to enhanced real-time data monitoring, predictive maintenance, and improved production capabilities. A report from Deloitte indicates that manufacturers using integrated automation can achieve up to a 20% increase in productivity, underscoring the critical role that modern vertical milling machines play in optimizing manufacturing operations and meeting the demands of an increasingly competitive landscape.

| Feature | Description | Advantages | Recent Innovations |

|---|---|---|---|

| Precision Control | Vertical milling machines provide superior control over cutting depths and angles. | Higher manufacturing accuracy, reduced material waste. | Integration of CNC technology for automated precision. |

| Versatility | Capable of handling a wide variety of materials including metals, plastics, and composites. | Flexibility in applications ranging from prototypes to large production runs. | Advanced tooling options and software that enhance material compatibility. |

| Reduced Setup Time | Quick-change tool technology minimizes downtime between job setups. | Increased productivity with less time spent on equipment preparation. | Cloud-based management systems for real-time scheduling and performance tracking. |

| Sustainability | Energy-efficient operations leading to reduced carbon footprint. | Lower operational costs and compliance with environmental regulations. | Emerging technologies focusing on energy recovery and waste reduction. |

| User-Friendly Interfaces | Modern machines feature intuitive controls and touchscreen interfaces. | Easier operation reduces training requirements and errors. | Augmented reality tools for enhanced operator guidance. |

5107 County Road C

Manitowoc, WI 54220

920-726-4526