920-726-4526

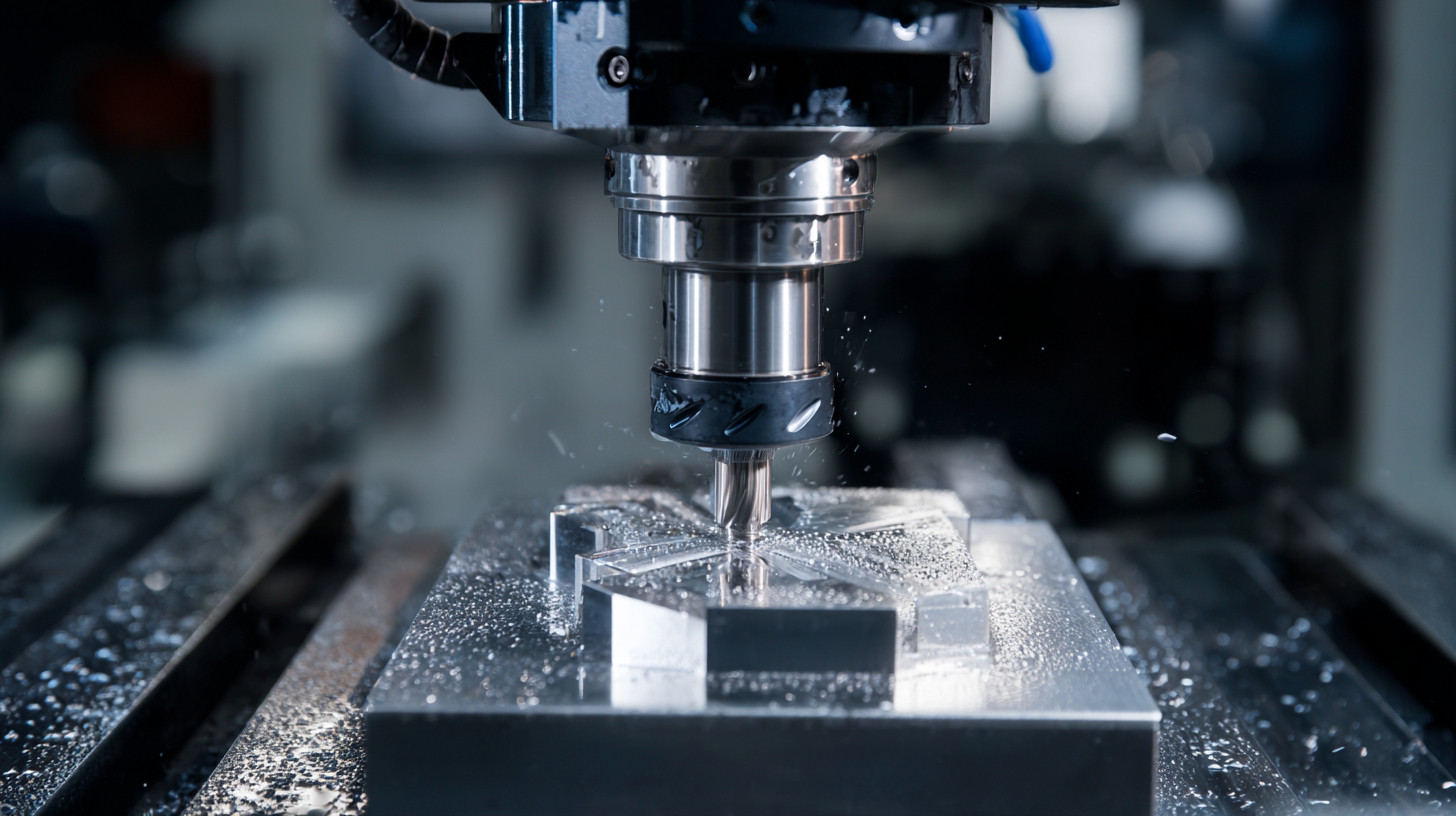

In an era where precision and efficiency are paramount, the integration of cutting-edge technology in manufacturing is essential for global competitiveness. The 5 Axis CNC Machine stands out as a pivotal innovation, revolutionizing the machining sector with its ability to perform complex cuts from multiple angles, significantly reducing production time and improving accuracy. As we look toward the technological advancements forecasted for 2025, businesses are increasingly recognizing the benefits of implementing sophisticated machinery like the 5 Axis CNC Machine in their operations. This blog will delve into the emerging trends in technology, the unparalleled advantages provided by 5 Axis CNC Machines, and how they align with global sourcing needs, ultimately enhancing productivity and driving growth in various industries. Join us as we explore how to unlock efficiency through the strategic adoption of these advanced machines.

The global CNC (Computer Numerical Control) machine market is on the rise, projected to reach a market value of $77 billion by 2024, bolstered by a compound annual growth rate (CAGR) of 5.5%. Within this booming sector, 5 Axis CNC machines are increasingly recognized for their ability to enhance efficiency and precision, making them indispensable for global sourcing operations. With their capability to machine complex shapes in a single setup, these advanced machines significantly reduce production time and improve overall workflow.

A recent market analysis indicates that the CNC machinery market could grow from $110.65 billion in 2024 to an impressive $182.34 billion by 2034. This dramatic growth highlights the rising demand for advanced manufacturing solutions, particularly in industries requiring high accuracy and versatile machining options. Companies looking to optimize their sourcing strategies would greatly benefit from investing in 5 Axis CNC technology, which not only streamlines operations but also ensures superior product quality through advanced surface control and maximized machining velocity. This innovation represents a critical shift in how manufacturers can meet the demands of an increasingly competitive global market.

| Feature | Description | Benefits | Application |

|---|---|---|---|

| Multi-Axis Movement | Ability to move along multiple axes simultaneously. | Increased machining options and flexibility. | Complex part manufacturing, aerospace components. |

| High Precision | Tight tolerances achieved through advanced technology. | Consistent quality and reduced rework costs. | Medical devices, automotive parts. |

| Speed of Production | Enhanced operational speeds compared to traditional CNC. | Faster time-to-market for products. | Consumer products, prototyping. |

| Material Versatility | Capabilities to machine a wide range of materials. | Ability to meet diverse client needs. | Electronics housing, custom tooling. |

| Cost Efficiency | Reduction in labor costs and material waste. | Improved profit margins. | High volume production. |

When choosing the best 5 Axis CNC machine for global sourcing needs, several key features can significantly enhance efficiency and precision. One paramount aspect is the machine's versatility; it should be capable of handling a wide range of materials and complex shapes. A machine with an effective multi-axis capability allows for intricate designs, reducing the necessity for multiple setups and subsequently streamlining the manufacturing process. Additionally, having a robust control system that supports advanced programming languages can facilitate intricate machining operations, enabling users to execute complex projects with ease.

Another essential feature is the machine's build quality and rigidity. High-quality components ensure that the machine can withstand the rigors of continuous use while maintaining accuracy throughout its lifespan. Look for heavy-duty frames and high-grade spindles, as these contribute to better vibration damping and stability during operation. Furthermore, the integration of modern technology, such as automatic tool changers and real-time monitoring systems, can further enhance productivity by reducing downtime and improving operational efficiency. Overall, by prioritizing these features, manufacturers can optimize their processes and maximize the benefits of their 5 Axis CNC machines.

When it comes to global sourcing, the choice of machinery plays a pivotal role in enhancing productivity and precision. Among the numerous options available, 5 axis CNC machines stand out due to their ability to perform complex tasks with ease. These machines allow for simultaneous movement along five different axes, thereby enabling the creation of intricate parts that are crucial in various industries such as aerospace, automotive, and healthcare. In this blog, we will explore the top five 5 axis CNC machines that can significantly boost your sourcing strategy.

The first machine worth considering is the Haas VF-5/50, which combines speed and flexibility. Its robust design ensures that it can handle heavier workloads while maintaining accuracy, making it ideal for large-scale production. Another top contender is the DMG MORI DMU 50, known for its intuitive interface and advanced technology that streamlines the machining process. Additionally, the Mazak Integrex series offers a unique multitasking capability, allowing manufacturers to complete multiple operations in one setup. These machines, among others, are essential tools for any sourcing strategy aiming for efficiency and quality.

In today's competitive manufacturing environment, 5 Axis CNC machines are revolutionizing production efficiency and quality by allowing intricate designs to be machined in a single setup. This capability minimizes the need for multiple fixtures and setups, dramatically reducing production time. The simultaneous movement of the machine's axes facilitates complex machining operations, enabling manufacturers to create highly detailed parts with precision that traditional machines cannot achieve.

Tip: When selecting a 5 Axis CNC machine, consider the specific applications you will be using it for. Research different models to find one that offers the versatility and features that align with your production goals. Investing in the right tooling can further enhance the capabilities of your machine, producing superior finishes and specifications.

Moreover, the improved design freedom offered by 5 Axis CNC machines allows for the optimization of parts, resulting in lightweight components without sacrificing strength. This not only maximizes material efficiency but also enhances the overall quality of the end products.

Tip: Implementing regular maintenance routines can keep your CNC machines running optimally. Staying proactive with machine upkeep will minimize downtime and prolong the lifespan of your equipment, ultimately supporting sustained production efficiency and high-quality outputs.

This bar chart illustrates the efficiency gains and production quality improvements achieved by using 5 Axis CNC machines across various industries.

The comparison between 5-axis CNC machines and traditional CNC machines remains a crucial topic in the realm of modern manufacturing. As industries push towards greater precision and efficiency, the capabilities of 5-axis systems are outpacing their traditional counterparts. The global CNC machine market is projected to experience significant growth, from $101.22 billion in 2025 to an impressive $195.59 billion by 2032, with a compound annual growth rate (CAGR) of 9.9%. This surge underscores a growing demand for advanced machining solutions capable of handling complex geometries with superior accuracy.

5-axis CNC machines offer notable advantages, such as the ability to machine parts from multiple angles without repositioning, significantly reducing cycle times and enhancing precision. For instance, the implementation of optimized dual NURBS curve interpolation in these systems improves path planning accuracy. A well-calibrated machine can achieve incredible levels of precision, as seen in the advancements in cutter contacting point trajectory prediction techniques that help minimize errors during machining.

Tips:

1. When considering a 5-axis CNC machine, evaluate its software capabilities for advanced path planning to ensure reduced setup times and increased efficiency.

2. Regular maintenance and calibration of the machine can vastly improve machining accuracy and prolong the lifespan of the equipment.

3. Ensure your team is trained on the latest technologies and techniques in CNC machining to maximize productivity and quality in production processes.

5107 County Road C

Manitowoc, WI 54220

920-726-4526