920-726-4526

As industries evolve towards the advanced paradigms of Industry 2025, the demand for Custom CNC Machining solutions has surged, driven by the need for precision, efficiency, and flexibility in manufacturing processes. According to the latest market research, the global CNC machining market is expected to reach USD 100 billion by 2025, with a compound annual growth rate (CAGR) of 6% from 2020 to 2025. This growth is attributed to advancements in technology and the increasing adoption of automation and robotics in manufacturing. Custom CNC Machining not only enhances product quality but also allows for the creation of complex geometries, making it indispensable for diverse sectors such as aerospace, automotive, and medical devices. As we delve into the technical specifications of the best custom CNC machining solutions, it becomes evident that understanding these innovations is key to unlocking the precision needed for future manufacturing success.

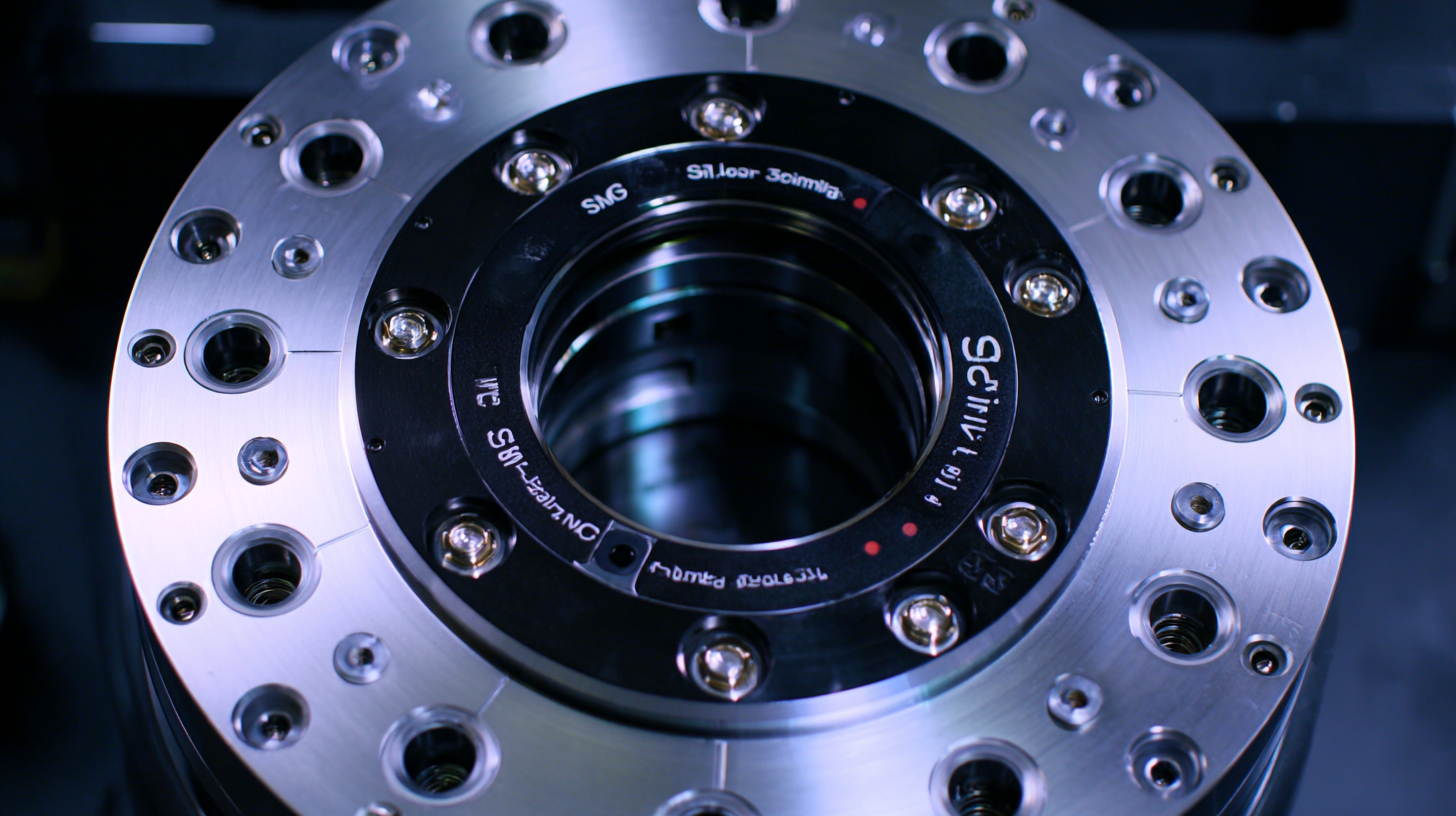

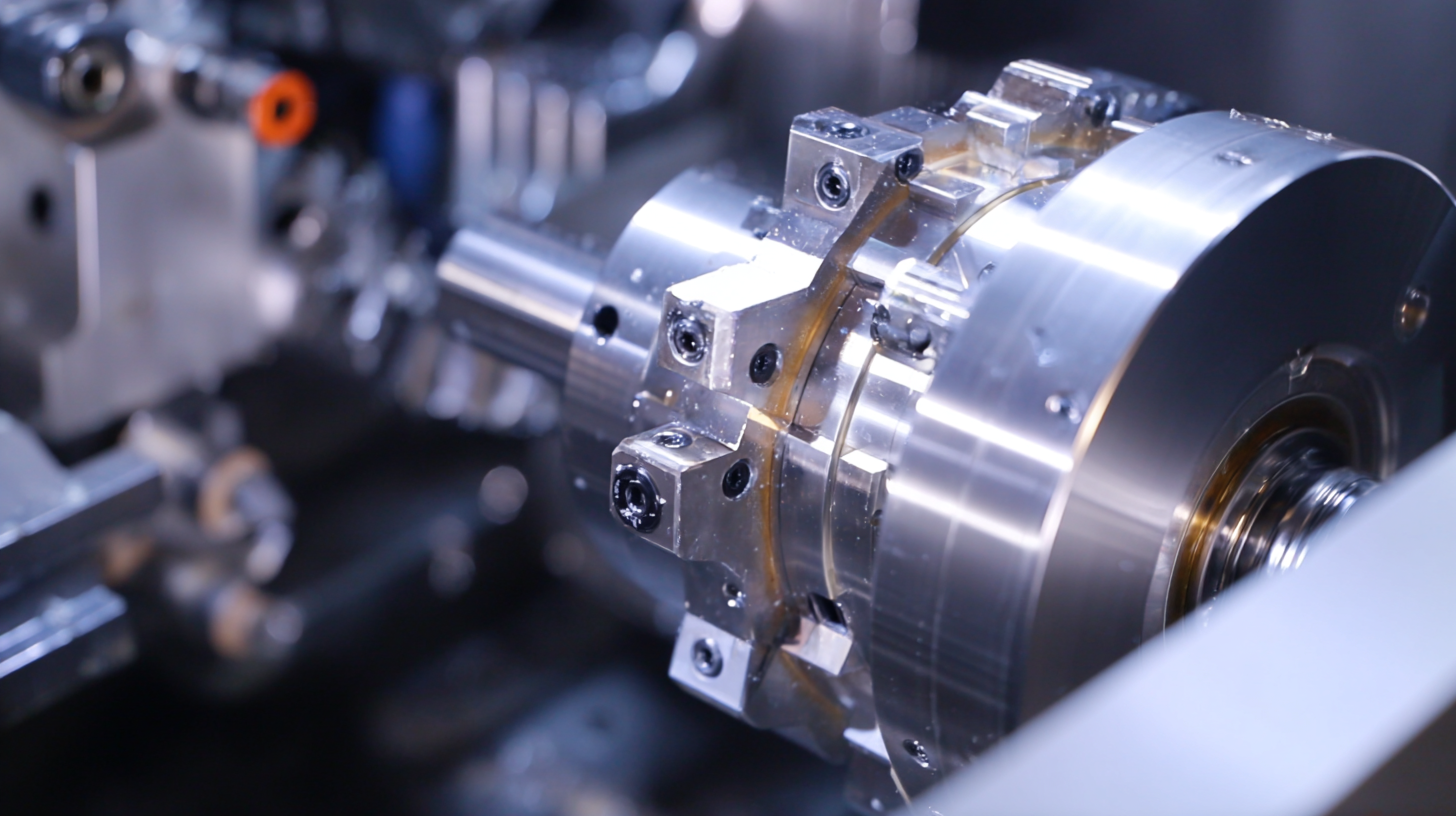

CNC machining has become an essential technology in modern manufacturing, allowing for unparalleled precision and efficiency. Key technologies within CNC machining include milling, turning, and electrical discharge machining (EDM). According to a report by MarketsandMarkets, the CNC machine market is projected to reach USD 117.31 billion by 2026, driven by advancements in automation and the demand for customized solutions. These machines offer tolerances as tight as ±0.005 mm, making them suitable for industries ranging from aerospace to medical devices.

CNC machining has become an essential technology in modern manufacturing, allowing for unparalleled precision and efficiency. Key technologies within CNC machining include milling, turning, and electrical discharge machining (EDM). According to a report by MarketsandMarkets, the CNC machine market is projected to reach USD 117.31 billion by 2026, driven by advancements in automation and the demand for customized solutions. These machines offer tolerances as tight as ±0.005 mm, making them suitable for industries ranging from aerospace to medical devices.

The technical specifications of CNC machines play a critical role in their performance. Factors such as spindle speed, feed rate, and tool selection can significantly impact the final product's quality and accuracy. For instance, high-speed machining (HSM) increases productivity, with spindle speeds exceeding 30,000 RPM reported in advanced machining centers. Furthermore, the integration of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems allows for seamless transitions from design to production, enhancing the overall efficiency of CNC operations. Such technologies are vital for meeting the growing demand for custom parts and components across various sectors.

In the ever-evolving world of custom CNC machining, the choice of materials plays a pivotal role in achieving precision and enhancing product performance. Cutting-edge materials such as aluminum alloys, high-strength plastics, and advanced composites have gained popularity due to their unique properties. Aluminum alloys, for instance, offer an exceptional strength-to-weight ratio, making them ideal for applications requiring lightweight yet durable solutions. Their adaptability to various CNC machining processes allows for intricate designs while maintaining structural integrity.

On the other hand, high-strength plastics like PEEK and PTFE provide excellent chemical resistance and low friction properties, which are crucial in industries such as aerospace and medical device manufacturing. These materials not only ensure durability but also help in reducing manufacturing costs due to their ease of machining. Additionally, composites, which combine multiple materials to exploit their strengths, are increasingly being used to meet specific performance requirements. This comparative analysis highlights how the selection of advanced materials directly influences the efficiency of custom CNC machining solutions, driving innovation and precision in manufacturing.

Precision in CNC machining is paramount for industries requiring high-quality components. According to a recent report from the International Organization for Standardization (ISO), CNC machined parts can achieve precision tolerances of ±0.01 mm, which is critical for applications in aerospace and medical fields. These stringent standards ensure that even the most intricate designs can be produced with the reliability necessary for mission-critical operations.

Implementing best practices in achieving and maintaining these precision tolerance levels involves a multifaceted approach, including optimal machine calibration, tool selection, and regular maintenance. The Machinery's Handbook suggests that the choice of cutting tools can significantly affect the quality of the finished product, with carbide tools often recommended for their durability and precision. Furthermore, statistical process control (SPC) has become a fundamental practice, enabling manufacturers to monitor and adjust processes in real-time, thus minimizing variances and ensuring consistent quality across production runs. As businesses increasingly leverage custom CNC machining solutions, adhering to these precision tolerance standards not only enhances product quality but also improves overall operational efficiency.

| Material Type | Precision Tolerance Level (mm) | Machining Process | Common Applications | Best Practices |

|---|---|---|---|---|

| Aluminum | ±0.02 | CNC Milling | Aerospace, Automotive | Use high-speed tooling |

| Steel | ±0.05 | CNC Turning | Manufacturing Equipment | Maintain tool sharpness |

| Titanium | ±0.03 | EDM | Medical Devices | Coolant procedures |

| Copper | ±0.01 | CNC Milling | Electrical Components | Regular tool replacement |

| Plastic | ±0.05 | CNC Routing | Consumer Products | Maintain proper feed rate |

The rise of automation in manufacturing has led to a significant surge in the demand for advanced CNC machining solutions. These machines not only enhance productivity but also ensure precision, making them indispensable in modern production environments. The global CNC Horizontal Machining Centres Market, for instance, is projected to grow significantly, reflecting the industry's focus on high-accuracy manufacturing processes fueled by advancements in AI technology.

To maximize the benefits of advanced CNC machines, manufacturers should consider implementing the latest features that enhance their operations. For optimal productivity, invest in machines that offer twin-spindle technology, as these can dramatically reduce cycle times and improve efficiency. Additionally, integrating automation solutions can further streamline workflows and minimize human error, ensuring consistent and accurate production.

Another key tip for businesses is to prioritize ongoing training for operators. As CNC technology evolves, it's essential that personnel are well-versed in new tools and techniques to leverage the full capabilities of their machinery. By fostering a culture of continuous learning, companies can not only boost their operational efficiency but also drive innovation in their manufacturing processes.

Custom CNC machining has proven to be a crucial aspect of modern manufacturing, significantly impacting ROI for businesses across various industries. According to a report from Grand View Research, the global CNC machining market size is projected to reach $100.8 billion by 2025, growing at a CAGR of 6.3%. This growth is fueled by the increasing demand for precision-engineered components in sectors such as aerospace, automotive, and healthcare. By investing in custom CNC solutions, companies can achieve high levels of accuracy and speed in production, resulting in reduced waste and improved operational efficiency.

Furthermore, a study by the National Association of Manufacturers highlighted that companies employing advanced CNC machining technologies reported an average productivity increase of over 20% compared to traditional machining methods. This productivity boost is a critical factor that enhances ROI, allowing for faster turnaround times and greater customer satisfaction. Additionally, utilizing CNC machining minimizes the cost associated with rework and part scrappage, further underscoring its cost-effectiveness. As organizations continue to navigate competitive markets, leveraging custom CNC machining technologies will be vital in maximizing their returns on investment while meeting quality standards.

5107 County Road C

Manitowoc, WI 54220

920-726-4526