920-726-4526

In today's fast-paced manufacturing landscape, the integration of CNC machine technology has become essential for optimizing workflows and enhancing productivity. According to a report by MarketsandMarkets, the CNC machine market is projected to reach USD 117 billion by 2026, driven by the need for automation and precision in production processes.

However, as industries increasingly adopt these sophisticated machines, they often encounter common problems that may hinder performance, including software integration issues, maintenance challenges, and skill gaps among operators. Addressing these challenges is crucial for maximizing the benefits of CNC machines and ensuring seamless operations.

By understanding and resolving these problems, manufacturers can fully leverage the capabilities of CNC technology, leading to increased efficiency and reduced operational costs.

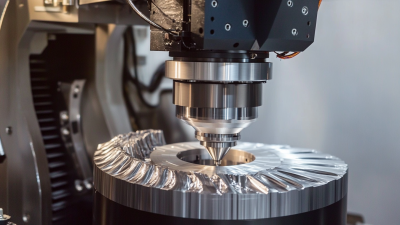

CNC machines have revolutionized modern manufacturing, delivering unparalleled efficiency and precision. One of the key benefits of utilizing CNC technology is the ability to automate repetitive tasks, which significantly reduces production time. By employing advanced software and hardware, CNC machines can operate continuously, leading to higher output rates without sacrificing quality. This automation allows manufacturers to focus on more complex design processes while ensuring that routine tasks are completed with extreme accuracy.

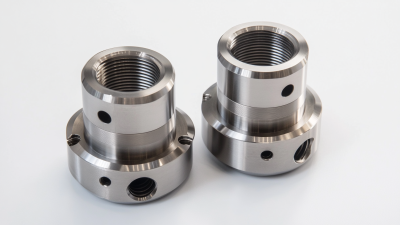

Moreover, CNC machines are equipped with advanced features that enhance precision in manufacturing processes. The ability to achieve intricate designs and exact specifications means that products are produced with minimal errors. This level of precision not only improves the quality of the final product but also reduces material waste, leading to cost savings in the production cycle. Consequently, the integration of CNC technology into manufacturing workflows promotes a culture of innovation and efficiency, enabling companies to maintain competitiveness in a rapidly evolving market.

The integration of CNC technology in manufacturing processes is proving essential for streamlining operations and reducing production time. Recent advancements highlight the transformative shift towards Industry 4.0, where seamless integration of design and manufacturing processes can enhance overall efficiency. For instance, the adoption of digital manufacturing technologies has significantly improved productivity across various industries, with reports indicating that organizations have experienced a marked reduction in production times by adopting CNC machines in their workflows.

Moreover, the incorporation of AI-powered tools into CNC operations is paving the way for smarter manufacturing solutions. Solutions like AI-assisted CAM software are rapidly gaining traction, enabling manufacturers to tackle complex programming challenges while expanding their capabilities. This digital transformation not only enhances precision but also contributes to cost control, making "first time right" a realistic goal for manufacturers. As industries increasingly rely on automation, the ability to create digital twins further enhances operational efficiencies, allowing for real-time adjustments and better resource allocation in CNC machining environments. This evolution signifies a pivotal moment in manufacturing, where technology integration is key to maintaining competitive advantages.

CNC machines have revolutionized manufacturing processes by enhancing workflow optimization through data-driven decision making. With the rapid advancements in artificial intelligence and robotics, manufacturers can now collect and analyze vast amounts of data to streamline operations effectively. According to recent industry reports, companies leveraging AI in machining have seen improvements in efficiency and production quality, achieving up to a 30% reduction in operational costs.

To further optimize your workflow with CNC technology, consider implementing IoT integrations. Machine learning algorithms can analyze real-time data from your CNC operations, identifying trends and inefficiencies. For instance, Project Kuiper successfully utilized data-driven insights from IoT to enhance their satellite manufacturing processes, emphasizing the importance of connecting machinery and leveraging data analytics.

Tip 1: Regularly audit your machining processes to identify bottlenecks. Data analysis should guide your decision-making to facilitate continuous improvements.

Tip 2: Invest in training your team on the latest CNC technologies and data interpretation techniques, making sure they are equipped to utilize the data generated effectively.

With a focus on data and technology, the future of CNC machining is brighter than ever, promising precision and adaptability that can transform traditional manufacturing practices.

As we look toward the future, CNC technology is set to revolutionize production efficiency across various industries. Emerging trends such as smart manufacturing, automation, and the integration of artificial intelligence are making CNC machines more intelligent and adaptable. These developments allow for enhanced precision, reduced cycle times, and optimized resource usage, streamlining workflows and reducing waste.

Tip: Implementing predictive maintenance on CNC machines can significantly minimize downtime. By utilizing sensors and AI algorithms, manufacturers can anticipate equipment failures before they happen, ensuring continuous operation and maximizing productivity.

Another major trend is the rise of additive manufacturing alongside CNC machining. This hybrid approach allows companies to produce complex parts that traditional machining methods may struggle with. Integrating these technologies not only opens up new design possibilities but also improves the overall efficiency of the production process.

Tip: Consider investing in training your workforce on these emerging technologies. Upskilling employees will not only enhance their productivity but also ensure that your operations remain competitive in an ever-evolving market.

In the rapidly evolving world of manufacturing, CNC machine technology has transformed workflows, enabling companies to enhance productivity and precision. Real-world case studies illustrate how organizations have successfully implemented CNC systems to optimize their processes. For example, a report from *Grand View Research* shows that the global CNC market is projected to reach $117.93 billion by 2027, indicating a significant shift towards automation and advanced machining solutions. Companies that have adopted CNC technology have reported efficiency increases of up to 30%, as they streamline operations and reduce human error.

To further optimize your workflow, consider implementing the following tips: First, assess your current workflow and identify bottlenecks that CNC machinery can address. Investing in CNC solutions designed specifically for your operations will yield the best results. Additionally, ensure that your team receives proper training on CNC systems. A *McKinsey & Company* report highlights that organizations which prioritize employee training see a 20-25% increase in productivity, as skilled staff can maximize the capabilities of advanced machinery.

Another case study showcases a manufacturer that integrated CNC technology into its assembly process, resulting in an impressive 40% reduction in lead times. By revisiting their workflow and aligning it with CNC capabilities, they enhanced output while maintaining high-quality standards. Emphasizing continuous improvement and adopting CNC technology can significantly transform your manufacturing processes.

| Case Study | Industry | CNC Technology Used | Improvements Achieved | Time Saved (hours/week) | Cost Reduction (% annually) |

|---|---|---|---|---|---|

| Automotive Parts Manufacturing | Automotive | CNC Milling | Increased precision and reduced waste | 15 | 20 |

| Aerospace Component Production | Aerospace | CNC Turning | Faster production times and enhanced quality control | 20 | 15 |

| Furniture Design and Manufacturing | Furniture | CNC Router | Streamlined design process and reduced lead times | 10 | 25 |

| Electrical Component Assembly | Electronics | CNC Laser Cutting | Higher accuracy and lower defect rates | 12 | 30 |

| Medical Device Manufacturing | Medical | CNC EDM | Improved product reliability and precision | 18 | 18 |

5107 County Road C

Manitowoc, WI 54220

920-726-4526