920-726-4526

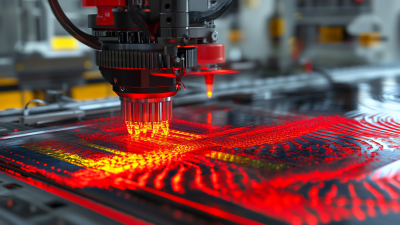

In today’s competitive manufacturing landscape, maximizing CNC machine efficiency is crucial for companies aiming to enhance productivity and reduce operational costs. According to a recent report by the National Association of Manufacturers, nearly 75% of manufacturers are prioritizing advanced technologies such as CNC machines to meet increasing production demands. Moreover, a well-optimized CNC machine can reduce lead times by up to 50%, as highlighted in the 2023 Global CNC Machinery Market Analysis. This guide presents 10 effective tips that can significantly improve the performance of CNC machines, enabling manufacturers to not only meet but exceed production goals. By implementing these strategies, businesses can harness the full potential of their CNC machines, ensuring optimal production within a rapidly evolving market.

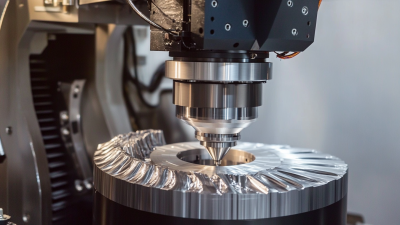

Maximizing CNC machine production hinges on a thorough understanding of cycle time and its influence on overall efficiency. Cycle time, defined as the total time taken to produce a part from start to finish, is a critical metric in manufacturing that directly impacts effectiveness and productivity. According to a study on Key Performance Indicators (KPIs) for production processes, optimizing cycle time can lead to significant reductions in operational costs—up to 20% in some industries. By streamlining machine operations and minimizing idle time, manufacturers can enhance output and maintain their competitive edge.

Moreover, factors such as the material being machined and the cutting parameters play a vital role in influencing cycle time. Research on the machinability of LM25 aluminum alloy reinforced with vanadium carbide indicates that adjusting the helix angle can reduce cutting forces and improve chip formation, which ultimately leads to faster cycle times. This relationship underscores the need for manufacturers to invest in advanced modeling techniques—such as analytical modeling combined with deep neural networks—to optimize machining parameters effectively. The adoption of such technologies not only drives efficiency but also contributes to sustainability by minimizing waste during the production process.

The chart above illustrates the time allocation for various aspects of CNC machine operations. By understanding where time is spent—cycle time, setup time, maintenance time, idle time, and operation time—manufacturers can identify areas for improvement to maximize efficiency and optimize production.

In the realm of CNC machining, optimizing tool path strategies can significantly enhance production efficiency and reduce machining time. A data-driven approach is essential in achieving these improvements. By analyzing historical performance data, manufacturers can identify bottlenecks in the machining process and fine-tune tool paths to minimize unnecessary movements. Implementing software that utilizes algorithms to calculate the most efficient route can lead to significant reductions in cycle time, thereby increasing overall productivity.

Moreover, leveraging simulation technologies allows companies to visualize tool paths before actual machining begins. This foresight enables operators to assess the efficiency of different strategies without incurring costs on time and materials associated with trial and error. As companies embrace IoT and real-time monitoring, they can continuously gather data during operations, refining tool paths dynamically to adapt to changing conditions. This proactive approach not only maximizes the efficiency of CNC machines but also contributes to higher quality production, ensuring that manufacturers remain competitive in an ever-evolving market.

Integrating IoT solutions into CNC operations revolutionizes how manufacturers monitor and optimize performance. Real-time monitoring enables instant feedback on machine conditions, which helps identify inefficiencies and maintenance needs before they escalate into costly downtime. With sensors providing data on vibrations, temperatures, and operational speed, operators can gain valuable insights to adjust settings for enhanced productivity.

One effective tip to maximize CNC machine efficiency is implementing predictive maintenance through these IoT solutions. By analyzing data trends, operators can schedule maintenance at the most opportune times, minimizing disruption. Additionally, ensuring proper staff training on how to interpret this data empowers teams to make informed decisions, leading to improved operational workflows.

Another tip involves leveraging automated alerts when performance metrics fall outside optimal ranges. This proactive approach facilitates immediate adjustments, keeping the production process smooth and efficient. Embracing IoT not only boosts CNC machinery performance but also fosters a culture of continuous improvement, ultimately paving the way for heightened productivity and profitability.

| Tip Number | Tip Description | Expected Impact (%) | IoT Integration |

|---|---|---|---|

| 1 | Regular maintenance schedule | 20 | IoT sensors for predictive maintenance |

| 2 | Optimize tool paths | 15 | Real-time path adjustments |

| 3 | Effective employee training | 25 | IoT-driven training sessions |

| 4 | Use high-quality materials | 30 | Material quality monitoring via IoT |

| 5 | Implement digital twin technology | 40 | Real-time simulation and data analysis |

| 6 | Schedule non-productive time wisely | 10 | Real-time production monitoring |

| 7 | Monitor machine performance metrics | 35 | IoT analytics for performance tracking |

| 8 | Enhance cooling systems | 20 | IoT temperature monitoring |

| 9 | Utilize advanced cutting tools | 28 | IoT tool wear monitoring |

| 10 | Analyze and feedback on operations | 15 | IoT data analytics for decision making |

In the competitive landscape of CNC machining, the efficiency of machine operations often hinges on the skill level of the operators. According to a report by the National Institute for Metalworking Skills, companies that invest in ongoing employee training witness a 30% increase in production efficiency. To truly maximize CNC machine efficiency, focusing on operator training and skill development is vital.

One effective tip is to implement a structured training program tailored to the specific machines and technology your team uses. Hands-on training allows operators to become intimately familiar with the machines, reducing error rates and downtime. Additionally, providing resources such as instructional materials and access to online courses can help operators stay up to date with the latest machining techniques and best practices.

Another key strategy is to encourage a culture of continuous learning. By regularly assessing skill levels and offering advanced training sessions, companies can enhance operator productivity. A study by Deloitte revealed that organizations with strong learning cultures have 34% higher employee retention rates, which translates to a more experienced workforce capable of driving higher output and operational excellence.

Routine maintenance is critical for maximizing the efficiency of CNC machines and minimizing downtime in production settings. According to a report by the Institute of Electrical and Electronics Engineers (IEEE), facilities that implement a structured preventive maintenance plan can reduce machinery downtimes by approximately 30%. Regular inspections, lubrication, and calibration help to identify potential issues before they escalate into costly breakdowns. By addressing these problems proactively, manufacturers can ensure that their production lines operate smoothly, ultimately enhancing overall productivity.

Incorporating technology into maintenance practices can further elevate machine performance. A study published in the Journal of Manufacturing Science and Engineering highlights that using predictive maintenance powered by IoT sensors can result in a 20% increase in operational efficiency. These sensors monitor machine performance in real-time, allowing for timely interventions and decreasing the chances of unexpected failures. As a result, businesses not only optimize their CNC machine usage but also improve their return on investment, making routine maintenance an indispensable aspect of modern manufacturing strategies.

5107 County Road C

Manitowoc, WI 54220

920-726-4526