920-726-4526

In the rapidly evolving landscape of manufacturing, precision is paramount, making high-quality machining services more crucial than ever. According to a report by Grand View Research, the global CNC machining market is projected to reach $100.73 billion by 2025, reflecting a compound annual growth rate (CAGR) of 8.0%. As industries increasingly lean on advanced technology to enhance production efficiency and minimize errors, leveraging expert machining services becomes essential for maintaining competitive advantage. Whether you’re working on custom parts for aerospace, automotive, or medical applications, understanding the various machining processes and selecting the best service providers can significantly impact the success of your projects. This comprehensive tutorial will serve as a checklist to guide you through the critical considerations, ensuring you harness the full potential of machining services for optimal results in your ventures.

In the world of machining services, post-sale support often becomes a critical factor for project success, yet it is frequently overlooked. The advantages of strong post-sale services can greatly influence the completion and longevity of machining projects. These services include technical support, maintenance, and repair assistance, all designed to ensure that the equipment and components function optimally long after the initial sale. With reliable support, clients can rest assured that any issues that arise will be handled promptly and professionally, thus minimizing downtime and enhancing project efficiency.

Moreover, thorough post-sale services can lead to better optimization of processes, as the service providers often engage in continuous communication with their clients. This feedback loop allows for adjustments and improvements based on real-world performance, ultimately leading to higher quality outcomes in future projects. Clients who invest in machining services with robust post-sale support not only benefit from immediate solutions but also gain valuable insights that can inform their strategies moving forward. Thus, prioritizing post-sale service offerings is a key component in maximizing the value and success of machining projects.

Maintenance costs are a crucial factor in the overall budgeting of machining services, often significantly impacting project feasibility and profitability. According to a recent report by the American Society of Mechanical Engineers (ASME), maintenance expenses can account for nearly 15-20% of the total operational budget in manufacturing environments. This highlights the necessity for effective planning and evaluation of these costs when selecting machining services.

In addition to direct expenses, the frequency and type of maintenance required can influence long-term financial commitments. The Manufacturing Institute noted that companies investing in preventive maintenance can reduce repair costs by up to 25%, demonstrating that a proactive approach can lead to significant savings. When choosing machining services, it's essential to consider the service provider’s maintenance record and their ability to adhere to industry standards, ultimately ensuring that projects remain on track and within budget while maintaining optimal machine performance.

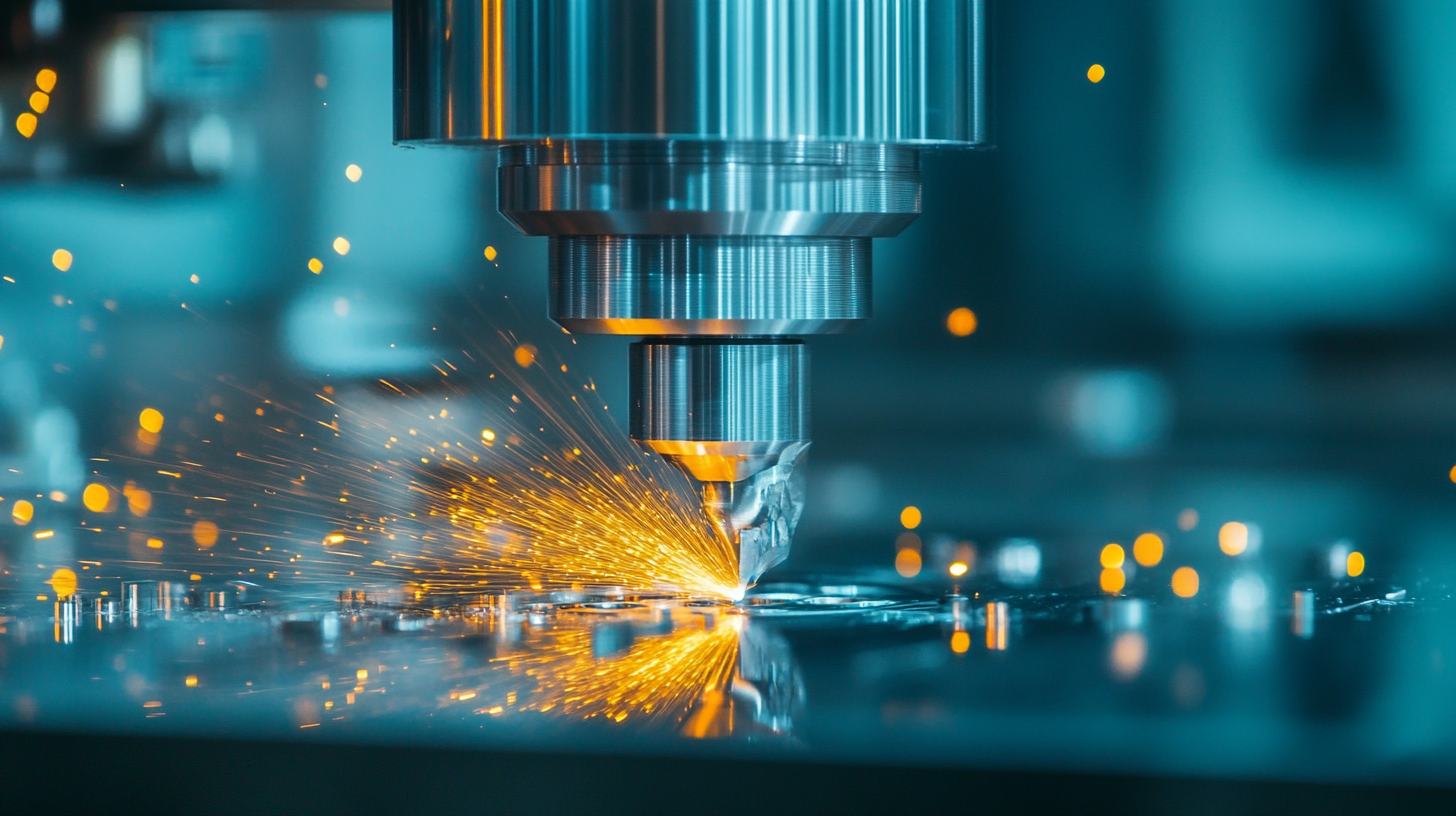

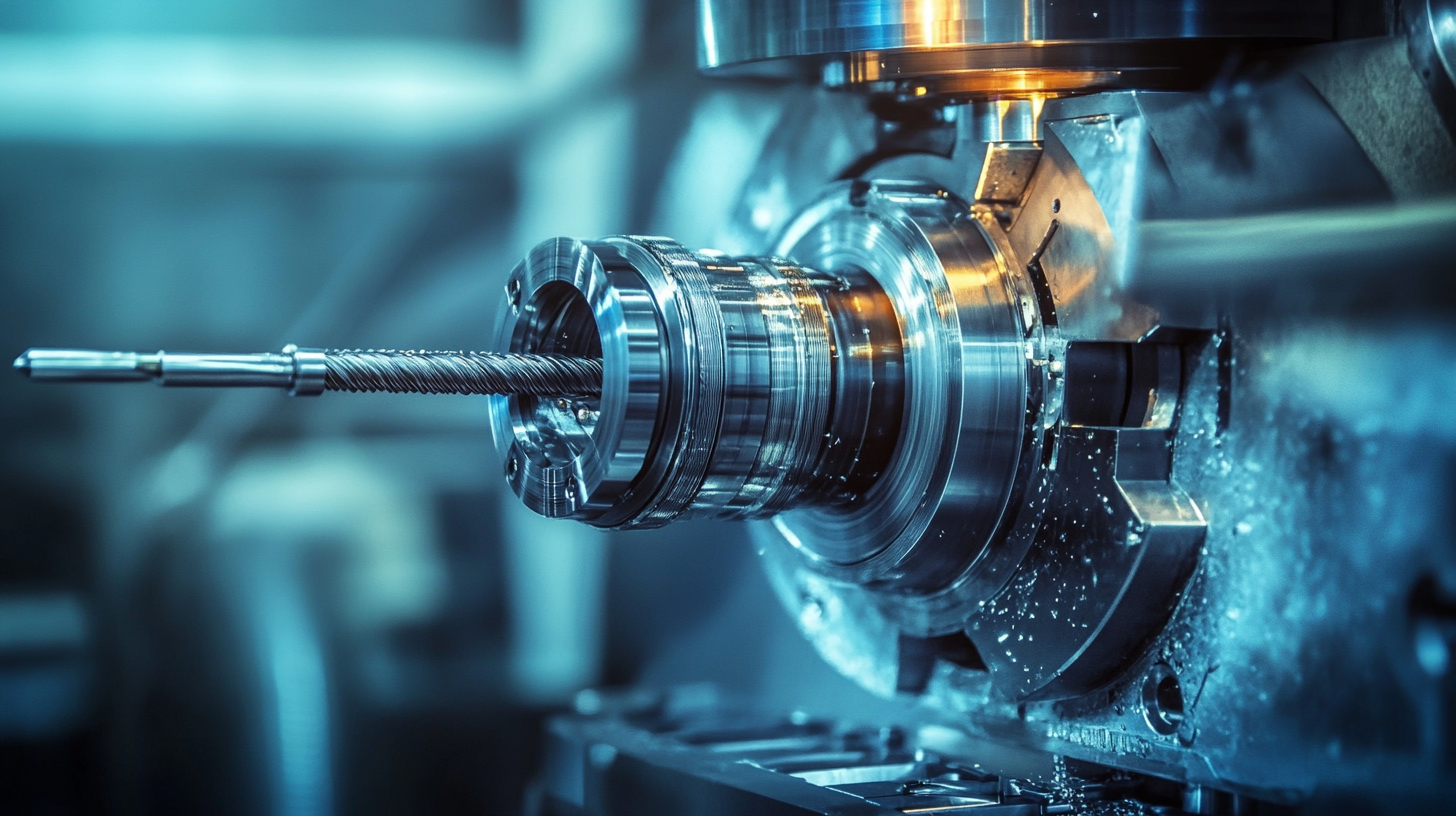

When selecting machining services for your projects, understanding the key factors that influence service quality is paramount. Precision is not just about the accuracy of a single cut; it encompasses the entire process from design to delivery. The expertise of the machinist plays a crucial role—experienced technicians can anticipate potential challenges, ensuring that the final product meets the required specifications. Additionally, utilizing advanced machinery and technology enhances the capacity for precision, allowing for tighter tolerances and more complex designs.

When selecting machining services for your projects, understanding the key factors that influence service quality is paramount. Precision is not just about the accuracy of a single cut; it encompasses the entire process from design to delivery. The expertise of the machinist plays a crucial role—experienced technicians can anticipate potential challenges, ensuring that the final product meets the required specifications. Additionally, utilizing advanced machinery and technology enhances the capacity for precision, allowing for tighter tolerances and more complex designs.

Another important factor is the quality of materials used in the machining process. The right material can significantly impact not just the durability but also the performance of the finished component. A reputable machining service will have an array of high-quality materials at their disposal and provide guidance on material selection based on the project needs. Moreover, strong communication between the client and service provider fosters collaboration, helping to clarify requirements and expectations. Together, these elements create a foundation for high-quality machining services that can bring your project to fruition effectively and efficiently.

When selecting a machining provider for your projects, after-sales support is a crucial aspect that should not be overlooked.

It encompasses the help and services provided to customers after they have purchased a product or service, ensuring satisfaction and long-term relationships.

Leading machining providers are increasingly focusing on their after-sales support to differentiate themselves in a competitive market.

This support can include a comprehensive warranty, regular maintenance services, and easy access to replacement parts, which can significantly extend the life of your machinery and reduce downtime.

Tips: When evaluating machining services, inquire about their after-sales support offerings.

Make sure they provide clear guidelines on how to access maintenance and repairs. Additionally, look for providers who offer training sessions to help you and your team maximize the use of the machinery.

Furthermore, strong after-sales support helps foster a partnership between you and the provider.

It can also lead to quicker response times in case of any issues, minimizing interruptions in your workflow.

A provider with a robust after-sales support system is often an indicator of a reputable and reliable machining service.

Tips: Always check customer reviews and case studies for insights into how a machining provider handles after-sales support.

This can reveal how responsive and effective they are in addressing customer needs post-purchase.

When it comes to machining projects, leveraging service agreements can make a significant difference in efficiency and cost-effectiveness. One of the key strategies is to clearly define the scope of work in the agreement. This includes specifying the materials to be used, the expected timelines, and any special tolerances that need to be met. By outlining these details, you minimize misunderstandings and ensure that both parties are on the same page, which is crucial for maintaining quality throughout the project.

Tip: Always include a clause for regular updates and communication in your service agreement. This creates a framework for ongoing dialogue, allowing you to adjust timelines if unforeseen issues arise and ensuring that the machining services align with your evolving project needs.

Another important aspect is to negotiate terms that include flexibility for future changes. Machining projects can often experience shifts in design or additional requirements, so having a service agreement that accounts for these variations can save time and resources. Establishing a good relationship with your service provider can lead to mutual benefits, where both parties can adapt to project changes with minimal disruptions.

Tip: Consider setting performance metrics in your agreement. This not only holds the service provider accountable but also provides you with measurable outcomes that ensure the project stays on track and meets your precision requirements.

5107 County Road C

Manitowoc, WI 54220

920-726-4526