920-726-4526

CNC manufacturing is rapidly becoming a cornerstone of modern production processes, significantly enhancing efficiency and precision across various industries. According to a report by Grand View Research, the global CNC machines market size was valued at $68.6 billion in 2020 and is projected to expand at a compound annual growth rate (CAGR) of 6.5% from 2021 to 2028. This growth is largely driven by the increasing demand for automation and the rising need for high-quality components in sectors such as aerospace, automotive, and medical device manufacturing. As businesses strive for competitive advantage in a fast-paced economy, mastering CNC manufacturing has become essential for both novices and seasoned professionals. This step-by-step guide will delve into the fundamentals of CNC manufacturing, empowering beginners to navigate this transformative landscape effectively.

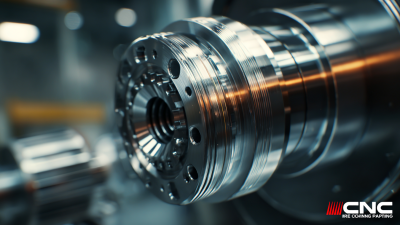

CNC manufacturing, or Computer Numerical Control manufacturing,

is a modern production technique that relies on computer systems to control machine tools. For beginners,

understanding the key concepts and terminologies surrounding CNC is crucial for navigating this complex field.

At its core, CNC technology automates the control of machining tools such as drills, lathes, and mills

through the use of programmed commands. These commands are typically written in G-code, a language that the machines

can interpret to perform precise movements and operations.

One important term to grasp is “machining”, which refers to the process of

removing material from a workpiece to achieve desired dimensions and surface quality. This can be achieved through

various methods including Milling, Turning, and Grinding. Additionally,

understanding “toolpaths” is essential; these are the predefined routes that

the cutting tools follow during the machining process. By familiarizing yourself with these concepts, you'll build

a strong foundation that will aid in mastering CNC manufacturing techniques as you progress in your learning journey.

When considering the types of CNC machines available in the market, it's essential to discern their specific applications and use cases. CNC milling machines, for example, have become ubiquitous in manufacturing due to their versatility and precision. They are ideal for machining complex geometries and are utilized in various industries, from automotive to aerospace. Recent advancements have shown that the integration of machine learning in CNC machining can dramatically enhance efficiency and quality. A report indicates that shops employing AI-driven CNC systems can see a productivity increase of up to 30%, driven by improved decision-making and predictive maintenance capabilities.

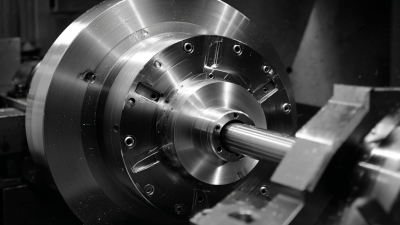

On the other hand, CNC lathes are specifically designed for rotational workpieces, providing high accuracy and finish quality, essential for producing parts such as shafts or cylindrical components. Their application further extends into industries focusing on intricate detailing, where the combination of automation and skilled programming has been reported to halve production time for complex designs compared to traditional methods. By understanding the core strengths and applications of various CNC machines, manufacturers can make informed decisions that align with their operational goals and technological advancements in the field.

When it comes to optimizing CNC manufacturing, choosing the right materials is crucial. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $100 billion by 2025, driven largely by advancements in material technologies. The selection of materials not only affects the performance of the final product but also influences cost-efficiency and machining capabilities. Common materials used in CNC machining include metals like aluminum and steel, as well as plastics and composites, each offering distinct advantages depending on the application.

Aluminum, for instance, is favored for its lightweight and corrosion-resistant properties, making it ideal for industries such as aerospace and automotive. In contrast, steel provides superior strength and durability, essential for heavy-duty applications. A survey conducted by the Precision Metalforming Association found that nearly 60% of manufacturers report that material selection significantly impacts production time and labor costs. Additionally, the emergence of advanced composites has expanded the boundaries of CNC machining, enabling manufacturers to create high-performance components with improved toughness and heat resistance. Understanding these material characteristics is essential for beginners aiming to achieve optimal results in CNC manufacturing.

When entering the world of CNC manufacturing, selecting the right software is crucial for both design and machining processes. Several leading programs dominate the market, each offering unique features tailored to different skill levels and project requirements. For beginners, user-friendly solutions like Fusion 360 and Easel provide intuitive interfaces and robust tutorials, making the learning curve less steep. These platforms allow users to quickly grasp the fundamentals of design, simulating machining processes and preparing them for actual production.

As one delves deeper into CNC machining, advanced software options like SolidWorks and Mastercam come into play. These programs offer extensive tools for design and CAM (computer-aided manufacturing) that cater to more complex projects. While they may require a steeper learning curve, they provide powerful capabilities for precise control over machining parameters, enabling manufacturers to optimize their workflows. By comparing these leading programs, beginners can identify which software aligns best with their skills and project goals, ensuring they start their CNC journey on the right foot.

| Software Name | Key Features | User Rating | Price Range |

|---|---|---|---|

| CAD Software A | 3D Modeling, Simulation, CNC Integration | 4.5/5 | $1,200 - $2,500 |

| CAM Software B | Toolpath Generation, Simulation, Optimization | 4.2/5 | $800 - $1,800 |

| Complete CNC Solution C | End-to-End Solution, Cloud-Based, Collaborative | 4.8/5 | $3,000 - $5,000 |

| Basic Design Tool D | 2D Design, Simple Layout, Easy to Use | 3.5/5 | $300 - $700 |

When considering CNC manufacturing techniques, a thorough cost analysis is crucial for beginners looking to manage their budgets effectively. The first step in this analysis is to evaluate the initial investment required for CNC machinery and software. Prices can vary significantly based on the type and capabilities of the equipment. For instance, entry-level CNC routers may be more affordable, but advanced mills and lathes could require a much larger capital outlay. Additionally, the software licenses for CAD/CAM programs can add to the startup costs, so it's essential to account for these when budgeting.

On the operational side, understanding the recurring expenses associated with CNC manufacturing is equally important. These costs include materials, tool wear, maintenance, and labor. Material costs can fluctuate based on market conditions, impacting overall profitability. Furthermore, as CNC machines can significantly reduce manual labor, it’s necessary to consider the potential savings from increased efficiency against the need for skilled workers to operate the technology. By weighing these financial aspects, beginners can gain a clearer picture of the financial sustainability of their CNC manufacturing endeavors and make informed decisions to optimize their operations.

5107 County Road C

Manitowoc, WI 54220

920-726-4526