920-726-4526

In today's competitive manufacturing landscape, the quest for unmatched excellence often leads companies to seek out the best machining services available. With China's manufacturing sector standing at the forefront of technological advancement and innovation, identifying high-quality suppliers is crucial for businesses looking to enhance their production capabilities and achieve superior results. This blog explores the key factors to consider when searching for top-tier machining services, highlighting the importance of supplier reliability, advanced technology, and a proven track record. By delving into the nuances of the Chinese machining industry, we aim to equip manufacturers with the insights needed to make informed decisions, ensuring they partner with suppliers who can propel their business to new heights of efficiency and quality.

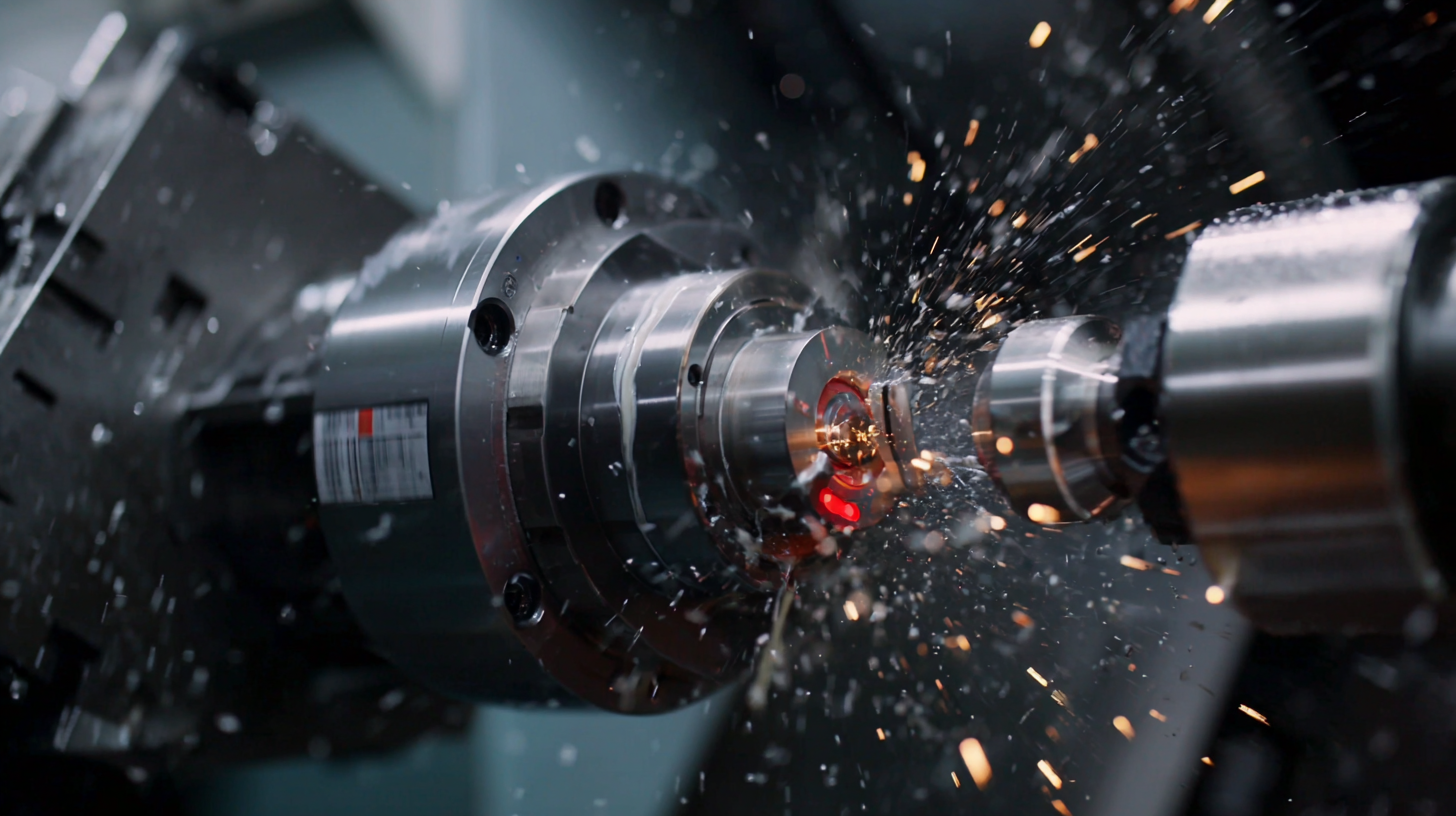

China's machining industry has earned a stellar reputation for its remarkable precision and quality control, setting the standard for global manufacturing. At the heart of this excellence lies a meticulous quality control process, which begins with selecting top-grade materials and advanced technologies. Leading machining services invest heavily in state-of-the-art machinery and software to ensure that every component meets stringent industry specifications. This commitment to quality is not just a procedure; it reflects a culture dedicated to continual improvement and innovation.

China's machining industry has earned a stellar reputation for its remarkable precision and quality control, setting the standard for global manufacturing. At the heart of this excellence lies a meticulous quality control process, which begins with selecting top-grade materials and advanced technologies. Leading machining services invest heavily in state-of-the-art machinery and software to ensure that every component meets stringent industry specifications. This commitment to quality is not just a procedure; it reflects a culture dedicated to continual improvement and innovation.

In addition to cutting-edge equipment, China's leading machining services emphasize comprehensive training programs for their workforce. Skilled technicians are well-versed in quality assurance protocols, enabling them to identify potential issues before they affect production. Regular audits and inspections further enhance product reliability, promoting a proactive approach to quality. By combining advanced technology with expert craftsmanship, these services not only meet client expectations but consistently surpass them, establishing a trust that keeps companies returning for their manufacturing needs. This dedication to quality control is what makes China's machining services unmatched on the global stage.

The global CNC machine market is on an impressive trajectory, expected to surge from $101.22 billion in 2025 to approximately $195.59 billion by 2032, reflecting a robust compound annual growth rate (CAGR) of 9.9%. This growth is being fueled by advancements in CNC technology, which enhance manufacturing precision and efficiency. As industries increasingly adopt automated solutions, the integration of advanced CNC systems is setting new benchmarks for productivity and cost-effectiveness.

In addition, the woodworking machinery market, which surpassed $4.9 billion in 2022, is anticipated to witness a steady growth rate of 4.5% from 2023 to 2032. This increase is largely driven by rising demand for woodworking machinery used in producing essential construction components, such as doors, windows, and cabinets. The convergence of advanced engineering and innovative design in CNC applications is revolutionizing the woodworking sector, facilitating customized solutions that meet diverse consumer needs and architectural trends. As a result, manufacturers are leveraging these technologies to stay competitive in a rapidly evolving marketplace.

China's machining services stand out in the global industry due to their unmatched precision and efficiency. With the machine tool industry value exceeding RMB 200 billion (approximately US$27.86 billion), China has cemented its position as the world's largest manufacturing powerhouse. This growth is driven by advanced technology and skilled labor, allowing Chinese companies to meet and often exceed global industry standards in terms of production speed and cost-effectiveness.

Comparatively, while Germany grapples with a decline in industrial production, China continues to innovate at a rapid pace. The latest reports indicate that China's manufacturing sector is pivotal to its economic rise, showcasing significant investments in AI and machine learning technologies. As a result, Chinese machining services not only lead in output but also in adopting advanced technological processes that enhance product quality. This positions China as a formidable opponent for established industrial players across the globe, making the need for competitive strategies more urgent than ever for industries reliant on precision engineering.

The manufacturing landscape in China has gained a reputation for unmatched excellence, largely due to the pivotal role played by a skilled workforce. Training programs focused on advanced machining techniques and technologies ensure that workers are not only familiar with traditional practices but are also well-versed in cutting-edge innovations. This blend of knowledge allows manufacturers to maintain high standards of precision and efficiency, setting them apart in a competitive global market.

Moreover, ongoing investment in workforce development is crucial for sustaining this competitive edge. Companies are increasingly partnering with educational institutions to create tailored training programs that address specific industry needs. This collaboration helps foster a culture of continuous improvement, where technicians and engineers are encouraged to upgrade their skills regularly. By cultivating a highly skilled labor pool, China's machining services are equipped to meet the evolving demands of various industries, further solidifying their leadership in manufacturing excellence worldwide.

When it comes to machining services, China has emerged as a global leader, driven by key performance indicators that define excellence in the industry. One of the primary metrics is precision manufacturing, which emphasizes the importance of tolerances and accuracy in dimensions.

Leading Chinese machining firms utilize advanced technologies such as CNC (Computer Numerical Control) machining, allowing them to achieve exceptional precision that meets stringent international standards.

Another critical performance indicator is efficiency, which is assessed through production turnaround times and resource optimization. By integrating lean manufacturing practices and automation, Chinese machining services have significantly reduced cycle times without sacrificing quality.

This commitment to operational excellence not only enhances productivity but also ensures that clients receive timely deliveries, fostering stronger partnerships across the globe. Ultimately, these key metrics reflect the commitment of Chinese manufacturers to maintain their position at the forefront of the machining industry.

5107 County Road C

Manitowoc, WI 54220

920-726-4526