920-726-4526

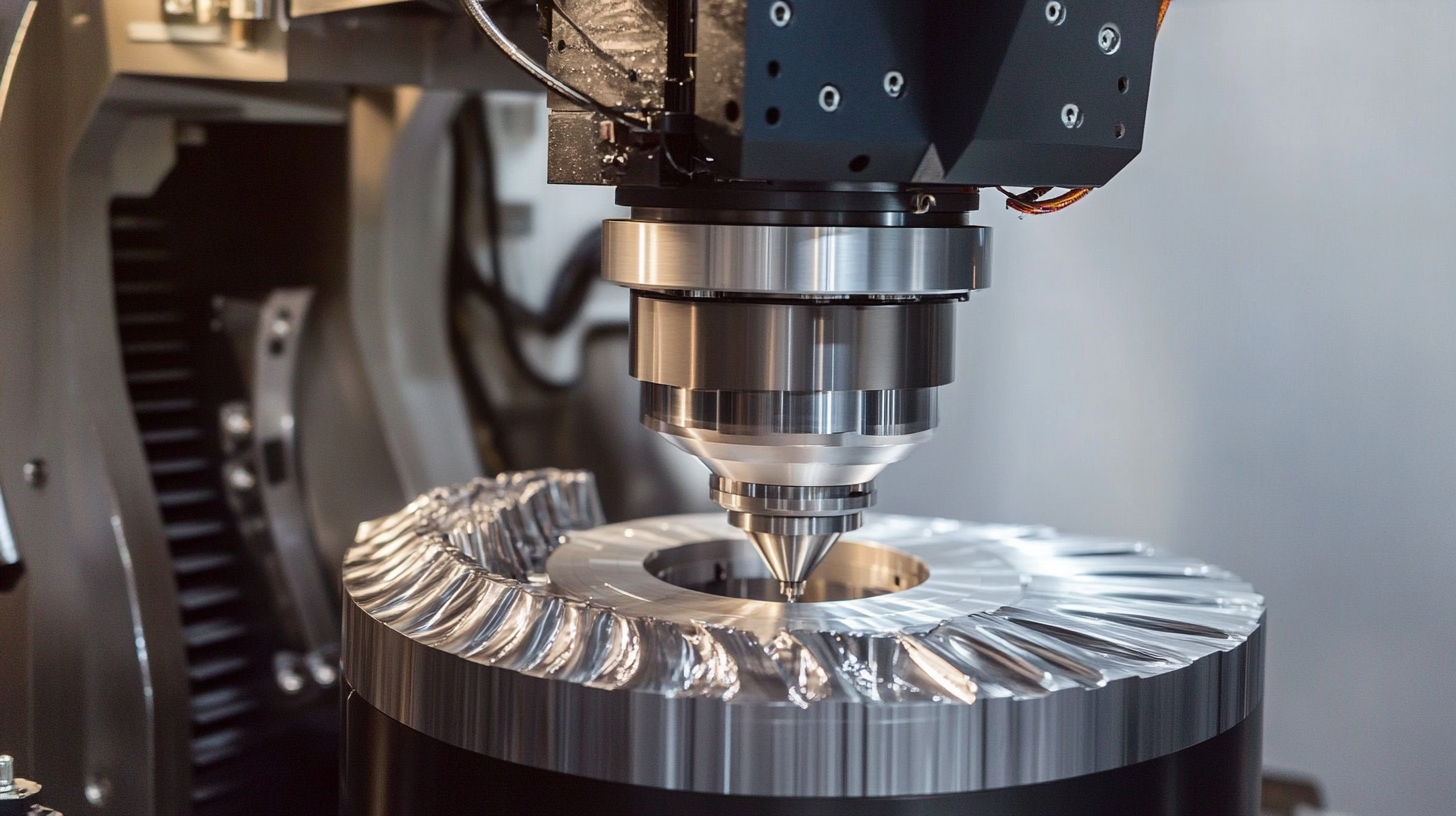

In the ever-evolving landscape of manufacturing technology, the 5 Axis CNC Machine stands out as a game-changer for industries seeking precision and efficiency. As we dive into 2023, understanding the key factors that distinguish the best 5 Axis CNC machines is essential for manufacturers looking to enhance their production capabilities.

In the ever-evolving landscape of manufacturing technology, the 5 Axis CNC Machine stands out as a game-changer for industries seeking precision and efficiency. As we dive into 2023, understanding the key factors that distinguish the best 5 Axis CNC machines is essential for manufacturers looking to enhance their production capabilities.

This ultimate guide will explore the critical elements that make these machines not only versatile but also indispensable in complex machining tasks. From superior motion control and advanced software features to robust build quality and exceptional support, we will highlight how these attributes contribute to improved accuracy and reduced cycle times.

Join us as we uncover the five key factors that elevate the top 5 Axis CNC machines above the competition, ensuring you make an informed decision for your operational needs.

In 2023, high-precision 5 axis CNC machines are distinguished by several key features that enhance their performance and versatility. One of the standout characteristics is their ability to achieve complex geometries with unparalleled accuracy, making them essential for industries like aerospace and automotive. These machines utilize advanced software algorithms that optimize tool paths, resulting in reduced machining time and improved surface finish.

Tips: When selecting a 5 axis CNC machine, consider the spindle speed and torque specifications. Higher spindle speeds can significantly decrease cycle times, while robust torque ratings allow for efficient machining of harder materials. Additionally, look for machines with adaptive control features, which can automatically adjust machining parameters based on changing conditions, ensuring optimal performance throughout the machining process.

Another notable feature is the integration of real-time monitoring systems that provide instant feedback on machining operations. This capability allows operators to detect potential issues before they escalate, minimizing downtime and reducing production costs. Machines equipped with smart technology further streamline workflows, enabling seamless communication between the CNC system and other aspects of the manufacturing process.

Tips: Always prioritize machines with user-friendly interfaces and comprehensive training resources. A machine that is easy to program and operate can drastically reduce the learning curve for your team and enhance productivity from the outset.

| Feature | Description | Impact on Performance | Typical Applications |

|---|---|---|---|

| High Precision | Increased accuracy in machining components. | Minimizes errors and reduces material waste. | Aerospace, Automotive, Medical Devices |

| Multi-Axis Capability | Ability to machine parts from multiple angles. | Enhances versatility and reduces setup time. | Complex geometries, Prototyping |

| High-Speed Machining | Fast movement and tool change rates. | Increases productivity and shortens lead times. | Mass production, Tooling |

| Advanced Software Integration | Use of CAD/CAM software for design and machining. | Streamlines workflow and enhances design flexibility. | Custom part manufacturing, Aerospace components |

| Robust Build Quality | Durable construction for longevity and reliability. | Reduces maintenance costs and failure rates. | Heavy-duty machining, Tool and die manufacturing |

In 2023, the landscape of 5-axis CNC machining is being transformed by innovative technologies that enhance performance and precision. One of the most significant advancements is the integration of advanced sensors and IoT connectivity. These technologies allow for real-time monitoring of machine performance, enabling operators to make data-driven decisions that optimize production efficiency. By tracking variables such as temperature, vibration, and tool wear, manufacturers can not only extend the lifespan of their equipment but also minimize downtime, paving the way for increased productivity.

Moreover, the adoption of artificial intelligence (AI) and machine learning in 5-axis CNC machines is revolutionizing how machining processes are approached. These intelligent systems can analyze operational data and recommend adjustments to improve machining accuracy and consistency. As a result, manufacturers can achieve higher quality finishes and reduce material waste, significantly affecting overall cost-effectiveness. This fusion of technology not only enhances the capabilities of 5-axis CNC machines but also enables manufacturers to stay competitive in a fast-evolving market.

When selecting a 5-axis CNC machine, material compatibility is crucial for achieving optimal results. Different materials, such as metals, plastics, and composites, all have unique machining requirements. Understanding these requirements can significantly influence the efficiency of your production and the quality of the final product.

**Tip:** Always evaluate the machine's spindle speed and torque characteristics in relation to the materials you will be working with. For example, softer materials like aluminum can benefit from higher RPMs, while harder materials require more torque at lower speeds. This ability to match machine parameters to material type will make a difference in cutting efficiency and tool lifespan.

Additionally, consider the machine's tooling compatibility with the intended materials. Certain tools are better suited for specific materials, such as carbide tools for harder metals or high-speed steel for softer materials. The right tooling not only enhances precision but also minimizes wear and tear on your equipment.

**Tip:** Invest in high-quality cutting tools that are tailored for your specific applications. This may seem like an additional expense initially, but it will pay off in the long run with increased productivity and reduced downtime due to tool failure. Always consult manufacturer specifications and recommendations to find the best match for your chosen materials.

The realm of CNC machining is continuously evolving, and user-friendly interfaces are emerging as a pivotal factor in the usability and accessibility of 5-axis CNC machines in 2023. According to a report by MarketsandMarkets, the CNC machine market is expected to grow to USD 100.3 billion by 2026, reflecting the industry's increasing focus on integrating advanced technologies that simplify operations. A significant portion of this growth can be attributed to advancements in user interface design, making cutting-edge CNC technology more accessible to operators of all skill levels.

Modern 5-axis CNC machines now come equipped with intuitive touchscreens and simplified software that allow users to program complex operations with ease. In fact, a survey by TechNavio revealed that 55% of manufacturers cited ease of use as a primary requirement when selecting CNC equipment. This emphasis on user-friendly design is not merely a trend but a necessity; as manufacturers seek to enhance productivity and reduce training costs, the growing prevalence of these interfaces ensures that even those new to CNC machining can operate sophisticated machinery effectively and confidently. As the industry progresses, we can expect continued innovation in user interfaces, further solidifying their role as a crucial factor in the selection of the best 5-axis CNC machines.

In 2023, the quest for cost-efficiency in 5-axis CNC machines has become paramount, especially for businesses looking to enhance profitability while maintaining high-quality output. A recent report indicates that manufacturers are increasingly adopting automation solutions to reduce operational costs, a trend driven by the need for efficiency in competitive markets such as aerospace. The integration of advanced technologies not only lowers production costs but also optimizes the machining process, allowing for more scalable operations.

Furthermore, the rise of collaborative environments and machining modules has made it easier to achieve a balance between quality and affordability. For instance, the introduction of low-cost, modular 5-axis systems indicates a shift towards accessible technology that can be integrated with existing 3-axis or 4-axis machines. This flexibility is crucial for shop owners aiming to meet diverse customer demands without significant capital investment. Recent advancements in rapid tooling techniques also provide opportunities for lower volume production at reduced costs, which aligns perfectly with the shifting focus toward custom, high-quality manufacturing solutions. The ongoing evolution of CNC technology continues to redefine what cost-efficiency means for modern manufacturers.

5107 County Road C

Manitowoc, WI 54220

920-726-4526