920-726-4526

The advent of Computer Numerical Control (CNC) technology has revolutionized the manufacturing landscape, enabling unprecedented precision and efficiency in production processes. According to a recent report by Mordor Intelligence, the global CNC market is projected to reach $100 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.5% from 2020 to 2025. This growth can be attributed to the increasing adoption of automation and smart manufacturing practices across various industries, including aerospace, automotive, and electronics. As manufacturers strive for higher productivity and lower operational costs, CNC systems are becoming integral to modern production strategies. By embracing innovative applications of CNC technology, companies not only enhance their capabilities but also position themselves to respond more effectively to market demands. In this blog, we will explore the transformative impact of CNC in contemporary manufacturing, highlighting key advancements and emerging trends that are shaping the future of the industry.

The evolution of Computer Numerical Control (CNC) technology has fundamentally transformed the landscape of modern manufacturing. From its inception, CNC machines have advanced from basic automated tools to sophisticated systems that enhance precision and efficiency. Recent reports highlight that the global CNC machine market surged to $55.1 billion in 2022, signaling robust growth driven by increasing demand for automation and precision in manufacturing processes. As industries embrace smart manufacturing, CNC technology plays a crucial role in facilitating high-performance productivity, making it an indispensable component of contemporary production facilities.

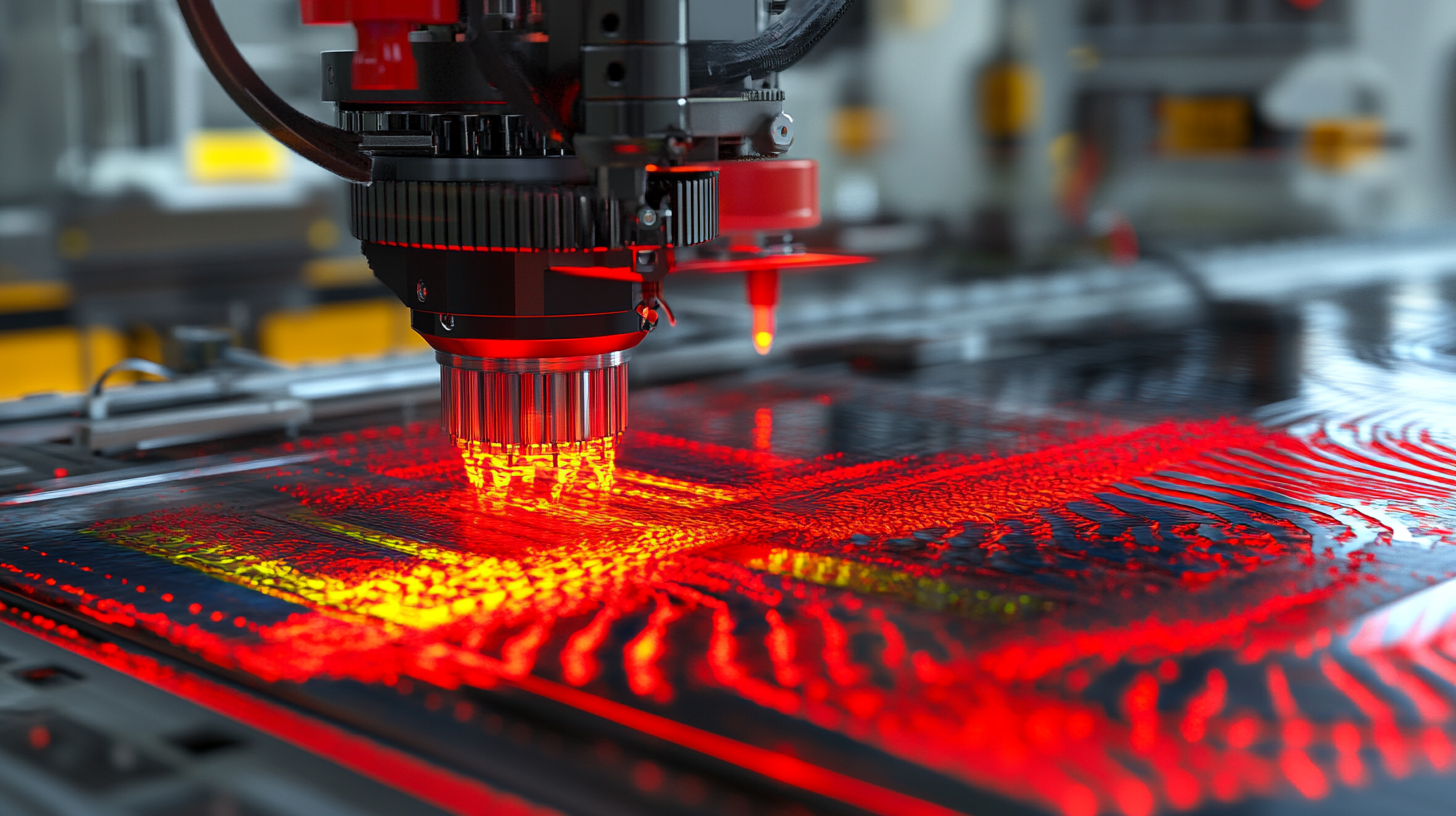

Emerging trends indicate that the integration of artificial intelligence and advanced simulation technologies into CNC systems is propelling their capabilities to new heights. The 5-axis CNC machining centers market, for instance, is expected to see remarkable expansion, fueled by innovations in self-optimization in machine cutting processes. This evolution not only enhances the quality of manufactured products but also significantly reduces wasted materials and time, reinforcing the industry’s commitment to sustainability. As the CNC market continues its trajectory of growth, driven by technological advancements, it becomes increasingly clear that this technology is at the forefront of revolutionizing how manufacturing operates globally.

The implementation of Computer Numerical Control (CNC) technology is revolutionizing modern manufacturing, offering a myriad of advantages that enhance production efficiency and precision. According to industry analyses, the global machine tool market is poised for substantial growth, with projections indicating a rise from $129.2 billion in 2025 to $230.42 billion by 2033, reflecting a Compound Annual Growth Rate (CAGR) of 7.50% during the forecast period. This remarkable expansion underscores the increasing reliance on advanced manufacturing technologies, particularly CNC, across various sectors including automotive, general machinery, and precision engineering.

CNC machines facilitate automation in production processes, drastically reducing manual errors and labor costs while boosting throughput. The automotive sector, in particular, benefits from CNC’s capability for high-volume parts manufacturing with tight tolerances, enabling a faster response to market demands. Furthermore, the adoption of Industry 4.0 principles emphasizes the integration of digital and intelligent technologies, transforming the landscape of the tool machine market. With China at the forefront of these advancements, the country's machine tool industry is set to embrace a golden revolution driven by technology transfer and innovation.

As industries continue to evolve, the strategic implementation of CNC technology will not only enhance productivity but also foster a greater level of competitiveness in the global market, positioning manufacturers to thrive in an increasingly digital world.

The aerospace and automotive industries are experiencing a transformative period thanks to innovative applications of Computer Numerical Control (CNC) technology. Recent advancements have highlighted the integration of artificial intelligence (AI) in CNC machining, which is driving unprecedented levels of precision and efficiency. According to a report from a leading industry analyst, the global CNC machine market is projected to reach $100 billion by 2025, underscoring the increasing reliance on automation and smart manufacturing techniques.

In aerospace, the use of CNC technology has allowed for the fabrication of lightweight composite structures, which play a crucial role in enhancing performance and fuel efficiency. With modern CNC machines capable of handling complex geometries, manufacturers can produce intricate parts that meet stringent safety standards while reducing material waste. A comprehensive review published in a recent industry journal revealed that lightweight materials can lead to weight reductions of up to 30%, significantly impacting overall aircraft performance.

The automotive sector is not lagging behind, as manufacturers embrace CNC technologies to streamline their production processes. The integration of AI not only enhances machining accuracy but also optimizes production schedules, ultimately reducing lead times. Reports indicate that companies adopting these advanced CNC solutions have achieved efficiency improvements of 20% to 30%, demonstrating the competitive edge offered by these innovations. As we continue to explore the potential of CNC applications, the future of manufacturing looks both exciting and promising.

The integration of Computer Numerical Control (CNC) with advanced technologies such as Artificial Intelligence (AI) and the Internet of Things (IoT) is transforming the landscape of modern manufacturing. The global CNC machine market size is projected to reach approximately $100 billion by 2027, growing at a CAGR of around 6% from 2023 to 2027. This growth is driven by increasing demand for automation and precision in sectors like automotive, aerospace, and general machinery.

By leveraging AI and IoT, manufacturers are enhancing the functionality of CNC machines, leading to improved operational efficiency and reduced downtime. For instance, predictive maintenance powered by AI algorithms allows for real-time monitoring and analysis of machine conditions, which can ultimately prevent costly operational interruptions. Additionally, IoT connectivity enables seamless data exchange between machines, leading to streamlined workflows and smarter factory environments.

In terms of application, sectors such as automotive and precision machinery are witnessing significant investments in CNC technology. The shift towards electric vehicles is also propelling the demand for precision CNC metal cutting and forming machines, ensuring manufacturers can meet stringent production requirements. As industries continue to adopt digital transformation strategies, the synergy between CNC technology and advanced technological integrations will play a crucial role in the evolution of manufacturing processes, making them more intelligent and automated.

The realm of Computer Numerical Control (CNC) systems is undergoing a transformative journey, driven by advancements in digital technology and the ever-evolving landscape of modern manufacturing. As industries harness the potential of CNC machines, the challenges in integrating these systems with emerging digital frameworks become increasingly evident. The push towards a fully digitized national innovation system emphasizes the necessity for robust digital infrastructure, which can support the supply capabilities of innovative CNC solutions.

However, the path forward is not without obstacles. Manufacturers must navigate issues such as data security, technological interoperability, and the need for skilled labor adept in operating advanced CNC systems. Furthermore, as we witness rapid globalization and market fluctuations, the adaptability of CNC systems to varying production requirements and supply chain dynamics will be crucial. Future trends likely will focus on enhanced automation, artificial intelligence integration, and real-time data analytics, ultimately leading to more efficient and responsive manufacturing processes.

Privacy, security, and the competition for technological supremacy are paramount as digital transformation unfolds globally. The successful evolution of CNC systems will not only rely on advancements in machine technology but also on fostering a collaborative approach within the national innovation ecosystem. The synergy between technological development and strategic support initiatives will shape the future landscape of modern manufacturing.

| Application Area | Innovative Techniques | Challenges | Future Trends |

|---|---|---|---|

| Aerospace Manufacturing | Additive Manufacturing with CNC | High precision requirements | Integration with AI for predictive maintenance |

| Automotive Industry | CNC Machining of Electric Vehicle Components | Short production cycles | Smart factories and IoT integration |

| Medical Devices | Customized prosthetics using CNC | Regulatory compliance | Biomaterials in manufacturing |

| Electronics | Micro-machining with high precision CNC | Complex designs and small tolerances | Quantum dot technology and integration with nanotechnology |

5107 County Road C

Manitowoc, WI 54220

920-726-4526