920-726-4526

In today's fast-paced manufacturing landscape, the demand for precision and efficiency has never been higher, compelling companies worldwide to seek innovative solutions that can keep them competitive. One such solution lies in the advanced capabilities of the 5 Axis CNC Machine, particularly those emerging from China, known for their remarkable efficiency and cutting-edge technology.

These machines are revolutionizing various industries — from aerospace and automotive to medical devices — by enabling complex geometries and intricate designs that traditional milling machines struggle to achieve. However, the adoption of 5 Axis CNC Machines is not without its challenges, including high initial costs, the need for skilled operators, and integration with existing workflows.

In this blog, we will explore compelling industry application cases of 5 Axis CNC Machines, the problems they may pose, and how these challenges can be overcome to unleash global innovation.

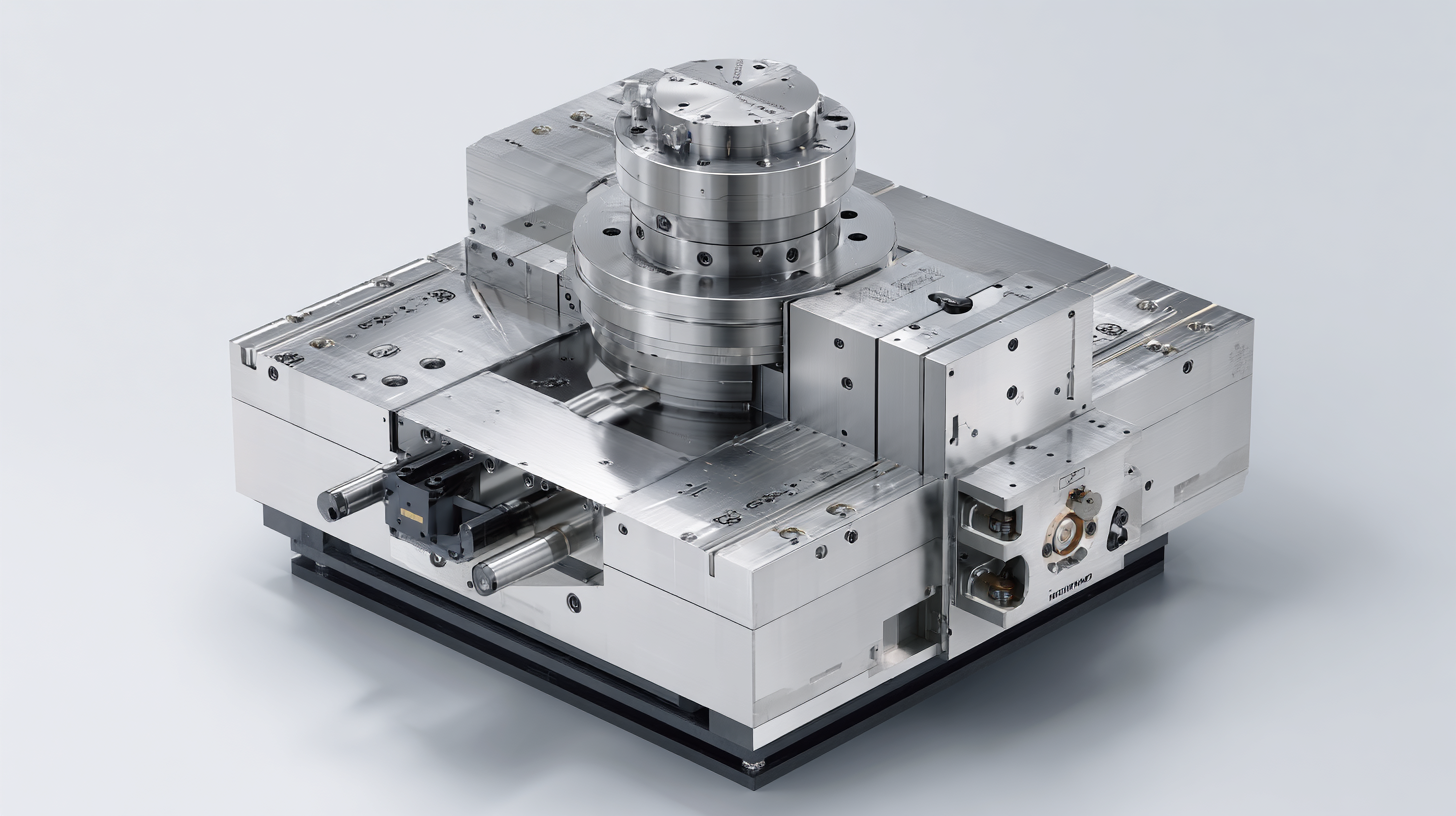

The advent of 5 axis CNC machines represents a significant turning point in modern manufacturing, fundamentally changing how products are designed and produced. Unlike traditional CNC machines that operate along three axes, 5 axis machines allow for movement across multiple planes simultaneously. This capability enables the creation of complex geometries and intricate designs with unparalleled precision, making them indispensable in industries ranging from aerospace to medical device manufacturing.

The strategic integration of 5 axis CNC technology into production lines fosters innovation by streamlining processes, reducing waste, and minimizing assembly time. By allowing for more advanced designs to be manufactured in a single setup, manufacturers can increase output while maintaining high standards of quality. Furthermore, the flexibility offered by these machines empowers engineers and designers to push the boundaries of creativity, leading to the development of innovative products that meet the demands of an ever-evolving market. The result is a manufacturing landscape that is not only more efficient but also brimming with potential for groundbreaking advancements.

The advent of 5 Axis CNC machines has transformed manufacturing processes globally, with China leading the charge in innovation. Key features of the best 5 Axis CNC machines from China include advanced automation capabilities, which enhance productivity and precision. According to a report from MarketsandMarkets, the global CNC machine market is projected to reach $100 billion by 2025, with a significant segment attributed to 5 Axis machines due to their efficiency in complex machining.

Another standout feature is their ability to provide multi-directional machining, which drastically reduces setup times and minimizes errors. A study from Research and Markets indicates that the 5 Axis CNC machine sector is expected to grow at a CAGR of over 8% from 2021 to 2026, largely driven by the demand for precision engineering in aerospace and automotive industries. This demand highlights the importance of investing in robust, high-performance machines that can maintain tolerances of less than 0.01 mm, which the best Chinese manufacturers consistently achieve through innovative designs and cutting-edge technologies.

In the realm of precision machining, the significance of 5-axis CNC machines cannot be overstated. A comparative analysis between Chinese 5-axis CNC machines and their global competitors reveals that China has swiftly positioned itself as a hub for advanced manufacturing technologies. According to a recent report by IDC, the global CNC machine market is projected to reach $100 billion by 2025, with China's share expected to increase significantly due to competitive pricing and technology improvements. Chinese manufacturers are investing heavily in R&D, leading to machines that not only meet but often exceed global standards in terms of precision and reliability.

Moreover, a study by Markets and Markets indicates that the demand for 5-axis CNC machines is growing at a CAGR of 6.2% until 2026. Chinese firms have leveraged this trend by offering highly adaptable solutions, providing manufacturers with advanced features such as multi-axis rotation and complex geometry capabilities. Companies like Haas and DMTG are leading the charge, presenting products at a fraction of the cost of European and American counterparts while maintaining high standards. This combination of innovation and affordability positions Chinese 5-axis CNC machines as formidable competitors in the global market, challenging established players and fostering a more dynamic manufacturing landscape worldwide.

| Feature | Chinese 5 Axis CNC Machines | Global Competitors |

|---|---|---|

| Price Range | $50,000 - $150,000 | $70,000 - $300,000 |

| Precision (μm) | ± 5 | ± 3 |

| Max Travel (mm) | 1000 x 800 x 600 | 1200 x 900 x 700 |

| Spindle Speed (RPM) | 12,000 | 15,000 |

| Material Compatibility | Aluminium, Steel, Plastic | Aluminium, Steel, Titanium |

| Typical Applications | Aerospace, Automotive, Electronics | Aerospace, Medical, Defense |

The adoption of 5-axis CNC technology has revolutionized the manufacturing landscape, enabling businesses to achieve unprecedented levels of precision and efficiency. One shining example is a Chinese aerospace supplier that implemented a state-of-the-art 5-axis CNC machining center. By leveraging this technology, they enhanced their production capabilities, significantly reducing lead times for complex components. The ability to simultaneously manipulate the workpiece along multiple axes allowed engineers to create intricate designs without the need for extensive setups, ultimately driving down operational costs.

Another compelling case involves a Chinese automotive parts manufacturer that embraced 5-axis CNC machining to improve the quality of their products. Faced with increasing demands for complex shapes and tighter tolerances, they transitioned from traditional machining techniques to advanced 5-axis systems. This shift not only streamlined their production process but also resulted in a remarkable 30% increase in output. With real-time monitoring and automated adjustments, the 5-axis machines ensured that the parts produced were consistently of high quality, meeting the rigorous standards of the automotive industry. Such successful implementations highlight how 5-axis CNC technology is pivotal in fostering innovation and enhancing competitiveness in various sectors.

The evolution of 5-axis CNC machines marks a significant turning point in the manufacturing sector, providing unprecedented precision and flexibility. As the global CNC machine market is projected to grow from $101.22 billion in 2025 to an astounding $195.59 billion by 2032, at a CAGR of 9.9%, industries are increasingly adopting advanced technologies to stay competitive. The demand for 5-axis CNC machining centers is expected to contribute to a market growth of USD 792.5 million from 2024 to 2028, driven by AI's role in optimizing machine cutting processes.

This transformative technology not only enhances production efficiency but also plays a crucial role in sustainability efforts. The focus on reducing waste and improving energy efficiency aligns with the broader movement towards a circular economy. With the pace of production reaching unsustainable levels, adopting innovative machining practices is vital for the future. As industries continue to embrace 5-axis systems, the implications on both economic and environmental fronts are profound, shaping a new era of manufacturing that prioritizes intelligent and sustainable operations.

This chart illustrates the adoption rates of 5 Axis CNC Machines across various industries from 2018 to 2023, highlighting the growing trend in the manufacturing sector.

5107 County Road C

Manitowoc, WI 54220

920-726-4526