920-726-4526

The cost of CNC machines is a crucial consideration for manufacturers and businesses aiming to automate their production processes. According to a report by Grand View Research, the global CNC machine market size was valued at approximately $69 billion in 2020 and is projected to expand at a compound annual growth rate (CAGR) of 5.6% from 2021 to 2028. This growth underscores the increasing adoption of CNC technology across various sectors, including aerospace, automotive, and medical device manufacturing. However, understanding the factors that contribute to CNC machine cost is essential for companies to make informed investment decisions and optimize their operations.

Several elements influence CNC machine cost, including the type of machinery, brand reputation, level of automation, and additional features such as advanced software and tooling. For instance, a report by IBISWorld highlights that while high-precision machines typically carry a premium price tag, they often result in higher productivity and reduced waste, translating to cost savings in the long run. As businesses navigate the complexities of CNC machine costs, it becomes imperative to evaluate these influencing factors comprehensively to maximize their return on investment and ensure sustainable growth in an increasingly competitive landscape.

When considering the cost of CNC machines, several key components come into play that significantly influence pricing. First and foremost is the type of materials used in the construction of the machine. High-quality steel and aluminum frames enhance durability and stability, which can drive up the price. Additionally, the precision of components such as linear guides and ball screws is a critical factor; more precise machine parts generally correlate with higher costs, reflecting their performance and longevity.

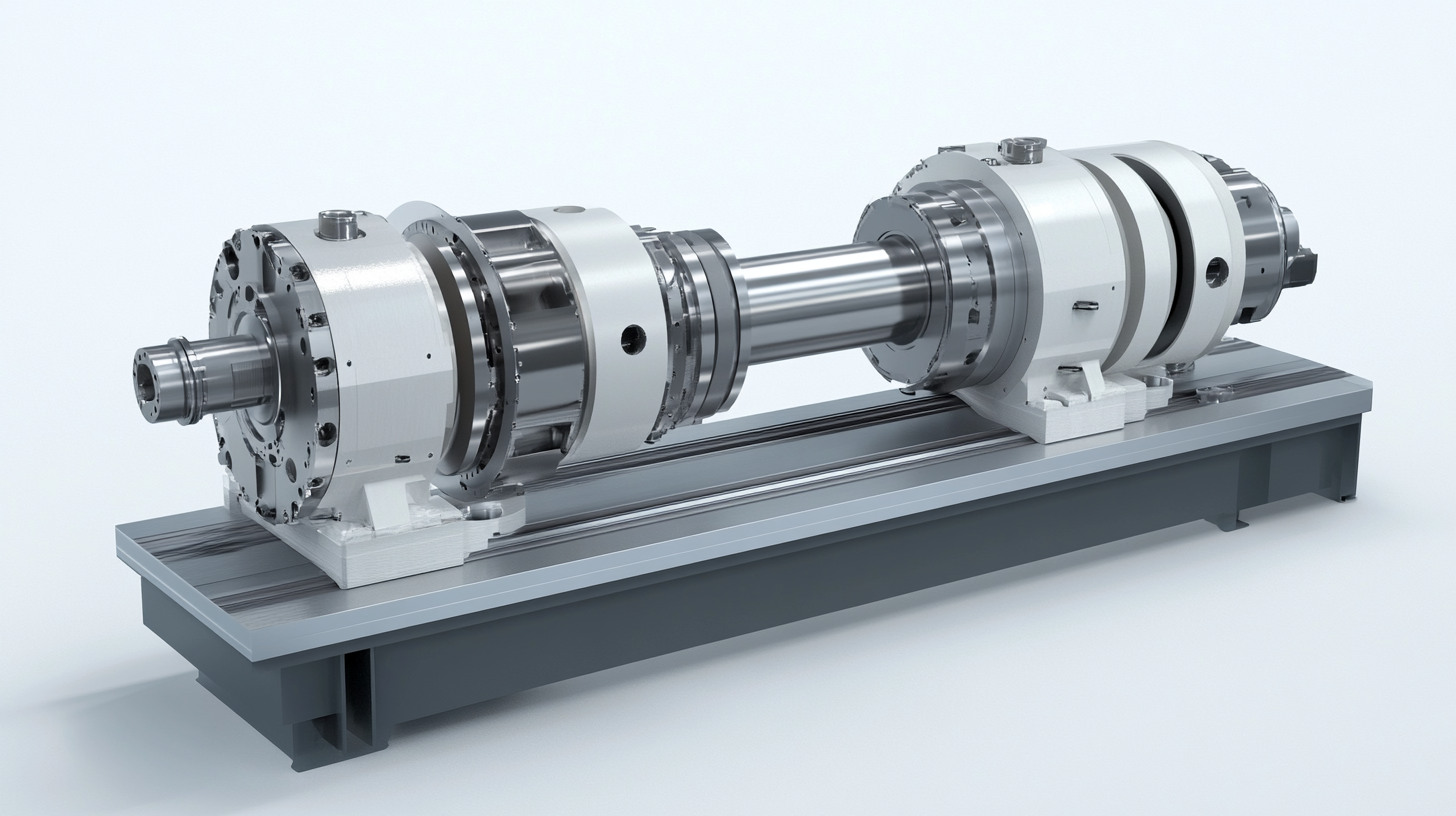

Another important element is the machine's capabilities and features. CNC machines can range from basic models to advanced systems equipped with multiple axes and sophisticated software. Machines that offer advanced features, such as automatic tool changers and enhanced control systems, are often priced at a premium. Furthermore, the machine's axis configuration—whether it’s 3, 4, or 5-axis—can significantly affect the cost, as more axes generally allow for greater versatility and complexity in machining tasks.

Lastly, support and warranty packages from manufacturers can influence machine pricing. Equipment that comes with comprehensive support, training, and extended warranties typically has a higher upfront cost, but can provide significant value over time by reducing downtime and maintenance expenses. Understanding these key components can help buyers make informed decisions when selecting a CNC machine that fits their budget and production needs.

When considering the cost of CNC machining, one of the most influential factors is the type of material being used. Different materials exhibit varying properties such as density, hardness, and machinability, all of which can significantly affect the overall machining costs. For instance, common materials like aluminum and plastics generally incur lower machining costs due to their ease of processing. In contrast, harder materials like titanium or certain alloys can demand higher rates because they require specialized tooling and longer machining times.

Additionally, the impact of material types extends beyond mere machining costs. Certain materials may also necessitate unique handling and finishing processes, further escalating the overall expenses. For example, stainless steel may require additional surface treatment to enhance corrosion resistance, adding to the time and cost of production. On the other hand, materials such as carbon fiber can offer lightweight advantages but may demand specialized equipment that can also increase costs.

In summary, understanding the implications of material selection is crucial for businesses aiming to optimize their CNC machining budget. By carefully evaluating material options, companies can better navigate the complexities of CNC machine costs, ensuring that they balance performance, durability, and affordability in their manufacturing processes.

This chart illustrates the impact of various material types on CNC machine costs. The data reflects average costs associated with different materials commonly used in CNC machining.

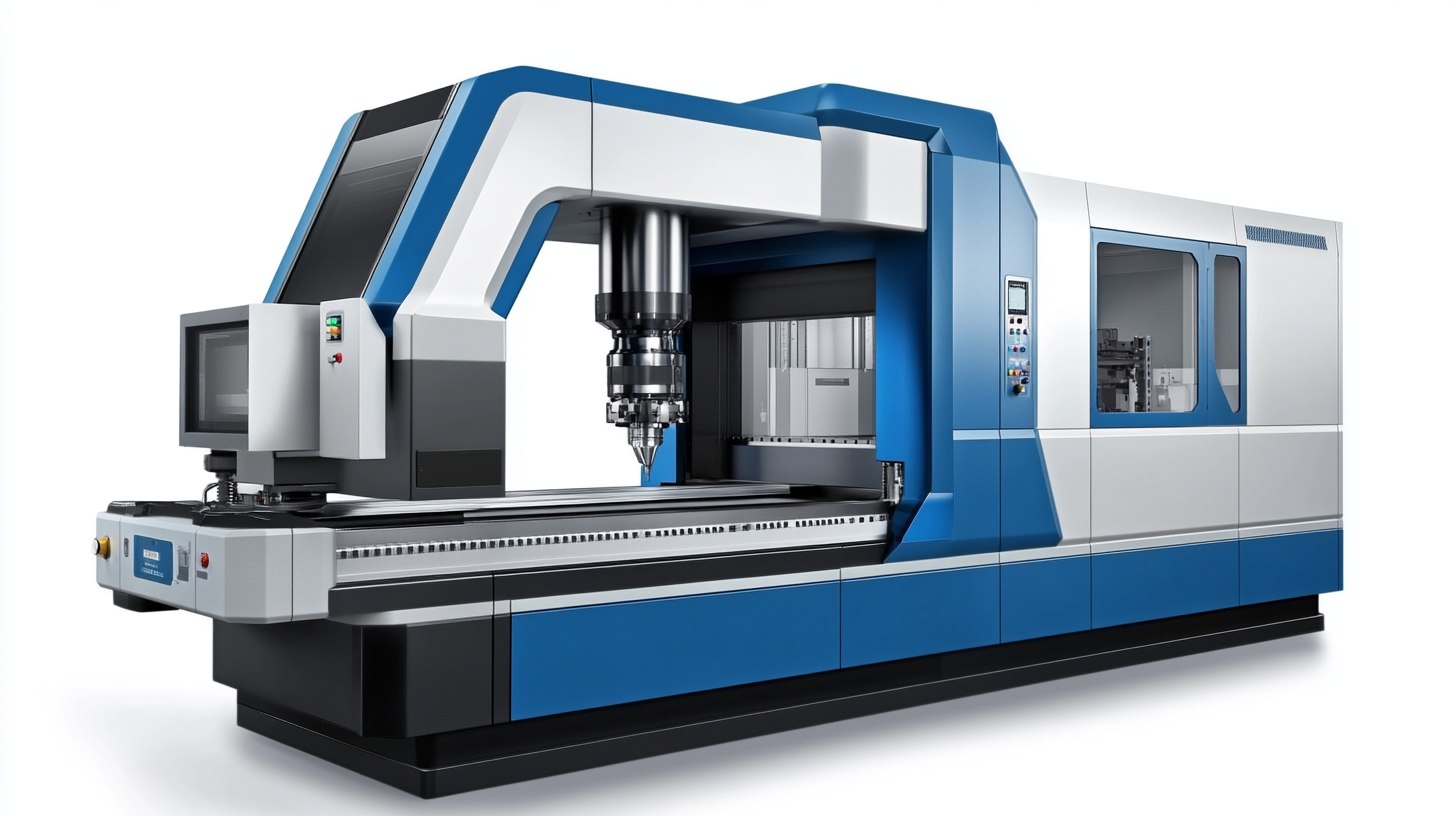

When it comes to CNC machines, their cost is influenced by various factors, but two of the most significant are machine size and complexity. The size of a CNC machine can directly correlate with its capacity and the size of the parts it can handle. Larger machines often have a higher price tag due to the costs associated with their physical build, transport, and space requirements. Additionally, the tooling and fixtures needed for larger machines can further add to the initial investment. For businesses that require large-scale operations, this could be a necessary expenditure to meet production demands effectively.

Complexity is another critical factor that impacts CNC machine pricing. Machines that come with advanced features, such as multi-axis capabilities or integrated automation, typically command higher prices. The technological sophistication required to operate these machines also necessitates a more thorough understanding and skilled labor, further inflating costs. Manufacturers must weigh the benefits of adopting complex machinery against the learning curve and operational investment required. Choosing the right balance between size and complexity is essential for businesses looking to optimize both their production efficiency and budget, emphasizing the importance of understanding these factors in the purchasing decision.

When it comes to the cost of CNC machines, brand reputation plays a crucial role in influencing pricing. Established brands that have proven reliability and performance often command higher prices due to their reputation for quality and customer support. According to recent market analyses, the CNC router machine market is projected to grow at a CAGR of 3.5% from 2024 to 2030, driven in part by consumers seeking machines from trusted manufacturers who have consistently delivered on their promises.

Moreover, as the demand for precision and efficiency in manufacturing rises, the investment in reputable CNC brands increases. Consumers are willing to pay a premium for machines that offer robust build quality and advanced technology features. The use of these machines in various industries, including woodworking and metalworking, further solidifies their value come resale time, as these brands tend to retain their worth better than lesser-known alternatives.

Furthermore, the rise of hybrid manufacturing technologies has expanded the marketplace, enabling consumers to evaluate their options closely. As newer companies enter the field, consumers are encouraged to compare options, but brand reputation will still be a touchstone for most procurement decisions. Research indicates that buyers are heavily influenced by peer recommendations and industry reviews when selecting CNC machines, leading to the continued prominence of reputable brands in a competitive landscape.

This pie chart illustrates the different factors that influence the cost of CNC machines, highlighting how brand reputation plays a crucial role in determining pricing.

When considering the long-term financial implications of CNC machine ownership, maintenance and operational costs play a crucial role. While the initial purchase price of a CNC machine can be daunting, it's essential to evaluate the costs associated with keeping the machine operational over time. Regular maintenance, which includes both preventative and corrective measures, ensures the machine functions at peak efficiency and prolongs its lifespan. Neglecting maintenance can lead to significant repair costs and downtime, ultimately affecting overall productivity and profitability.

Moreover, operational costs extend beyond just maintenance. They encompass energy consumption, labor, and the costs associated with materials used during the machining process. As industries face rising energy prices and potential supply chain disruptions, these operational expenses can escalate quickly. Companies must account for these variances when budgeting for CNC machining activities, as fluctuations in operational costs can impact financial stability.

With advancements in technology, such as the integration of artificial intelligence, manufacturers are presented with opportunities to optimize these costs. AI-driven analytics can enhance operational efficiency, predict maintenance needs, and ultimately lead to a decrease in both maintenance and operational expenses. As the manufacturing landscape continues to evolve, understanding these long-term financial considerations will be vital for companies aiming for competitiveness and sustainability in an increasingly challenging economic environment.

5107 County Road C

Manitowoc, WI 54220

920-726-4526