920-726-4526

In today's manufacturing landscape, the demand for customized products is at an all-time high, with the global CNC machining market projected to reach USD 116.8 billion by 2026, growing at a CAGR of 5.7% from 2021.

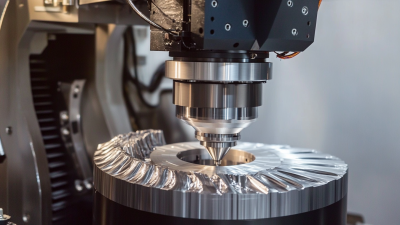

One Off CNC Machining has emerged as a key technique for industries seeking precision and flexibility in producing unique parts and prototypes. According to a recent report by SME, over 70% of manufacturers are adopting CNC machining technologies to stay competitive while addressing the need for rapid prototyping and low-volume production runs. As businesses increasingly embrace the benefits of One Off CNC Machining, mastering the related techniques becomes essential for achieving high-quality results and optimizing operational efficiency.

This blog will explore five essential tips that can help you excel in this specialized segment of CNC machining, ensuring that you can meet the complex demands of the market effectively.

One Off CNC Machining has emerged as a key technique for industries seeking precision and flexibility in producing unique parts and prototypes. According to a recent report by SME, over 70% of manufacturers are adopting CNC machining technologies to stay competitive while addressing the need for rapid prototyping and low-volume production runs. As businesses increasingly embrace the benefits of One Off CNC Machining, mastering the related techniques becomes essential for achieving high-quality results and optimizing operational efficiency.

This blog will explore five essential tips that can help you excel in this specialized segment of CNC machining, ensuring that you can meet the complex demands of the market effectively.

Understanding the basics of one-off CNC machining techniques is crucial for anyone looking to enhance their fabrication skills. One-off machining refers to the process of creating a single, unique component rather than mass-producing items. This approach is often employed in custom projects, prototypes, or repair parts, where precision and adaptability are key. The ability to program and operate CNC machines proficiently allows machinists to bring intricate designs to life with minimal waste and maximum efficiency.

One essential tip for mastering these techniques is to become familiar with the CNC software. Understanding how to utilize different tools, settings, and simulations will empower you to create more complex geometries while minimizing errors.

Another important aspect is paying attention to material selection. Not all materials respond the same way to machining, so selecting the appropriate type can significantly affect the outcome and durability of the final product. Lastly, maintaining a diligent process control is vital. Regular calibration of your CNC machine and meticulous monitoring during production ensures that you achieve consistent quality in your one-off creations.

When it comes to mastering CNC machining techniques, successful setup is critical. Understanding the market dynamics can aid in effective planning and execution. The global CNC machine market is projected to grow significantly, from $101.2 billion in 2025 to $195.59 billion by 2032, reflecting a robust compound annual growth rate (CAGR) of 9.9%. This growth indicates an increasing adoption of CNC technologies, which offer precision and efficiency in machining processes.

Key factors for successful CNC setup include selecting the right equipment and optimizing the machine's parameters. The rapid rise in the CNC machine market is influenced by advancements in technology and the growing trend of industrial automation. Additionally, the CNC machining landscape is complemented by expanding markets for related technologies, such as metal cutting tools, which are expected to increase from $86.24 billion in 2025 to $141.65 billion by 2032, marking a 7.3% CAGR. This synergy highlights the importance of integrating innovative solutions within the CNC setup to enhance productivity and meet industry demands.

When embarking on one-off CNC machining projects, having the right tools and software is crucial for achieving precision and efficiency. Essential tools include high-quality CNC machines that can accommodate various materials and sizes, as well as cutting tools tailored for specific tasks. Investing in a reliable workbench and proper clamping systems will also ensure safety and stability throughout the machining process.

In addition to physical tools, software plays a significant role in one-off projects. CAD (Computer-Aided Design) software is vital for creating precise designs, while CAM (Computer-Aided Manufacturing) software translates these designs into machine instructions. Having a good grasp of both types of software will empower you to optimize your designs and workflows, minimizing errors and maximizing output quality.

To master one-off CNC machining techniques, remember these tips:

When delving into one-off CNC machining, avoiding common mistakes can be the difference between a successful project and frustrating setbacks. A report from the International Journal of Advanced Manufacturing Technology indicates that nearly 30% of CNC machining errors are due to programming mistakes. Ensuring the accuracy of your G-code is paramount. It's crucial to double-check all parameters—dimensions, feeds, and speeds—before initiating the machining process.

Moreover, overlooking proper tooling can lead to diminished efficiency and quality. According to a survey by Modern Machine Shop, 55% of machinists reported that selecting the wrong tool adversely affected their fabrication work. To avoid this pitfall, select tools that match the material type and desired finish. For instance, carbide tools are excellent for steel, while high-speed steel works better with softer materials.

Another common oversight is neglecting post-machining processes. Many technicians underestimate the importance of finishing techniques, which can significantly enhance the part's performance and aesthetic appeal. Simple steps like deburring and applying protective coatings can improve longevity and usability, adding substantial value to one-off projects. Always dedicate time for these crucial finishing touches, as they are key to achieving professional-grade results.

In the realm of CNC machining, quality control and finishing touches are crucial in ensuring that the end product meets stringent industry standards. According to a report by Mordor Intelligence, the global CNC machining market is expected to grow at a CAGR of 7.5% from 2020 to 2025. This growth highlights the increasing demand for precision and quality in manufacturing processes.

Implementing rigorous quality control measures can significantly enhance the outcomes of one-off CNC machined parts. Techniques such as Statistical Process Control (SPC) can help operators monitor and control the machining process, thereby reducing defects and ensuring high-quality output.

Moreover, proper finishing touches are essential for optimizing the performance and aesthetics of machined components. An article from the Precision Engineering Journal emphasizes that up to 80% of machining defects can be attributed to inadequate finishing techniques. Methods such as deburring, polishing, and coating not only improve surface finish but also extend the lifespan of components.

By focusing on these finishing techniques, manufacturers can achieve tighter tolerances and better surface quality, resulting in a more competitive position within the market. Ensuring these elements are addressed is vital for any manufacturer aiming for long-term success in the CNC machining landscape.

5107 County Road C

Manitowoc, WI 54220

920-726-4526