920-726-4526

In today's competitive manufacturing landscape, selecting the right equipment can significantly impact a business's efficiency and output. Among the various machines available, the Horizontal Milling Machine stands out for its versatility and precision. This guide aims to provide comprehensive insights into choosing the best Horizontal Milling Machine tailored to your specific business needs. With a focus on quality, we will explore factors such as machine specifications, manufacturer reliability, and technological advancements. Whether you are a small workshop or a larger factory, understanding how to select a Horizontal Milling Machine that offers exceptional performance can enhance your production capabilities and contribute to achieving operational excellence. As China continues to emerge as a leading source for superior manufacturing solutions, this guide will also highlight how partnering with reputable Chinese factories can unlock outstanding product quality for businesses worldwide.

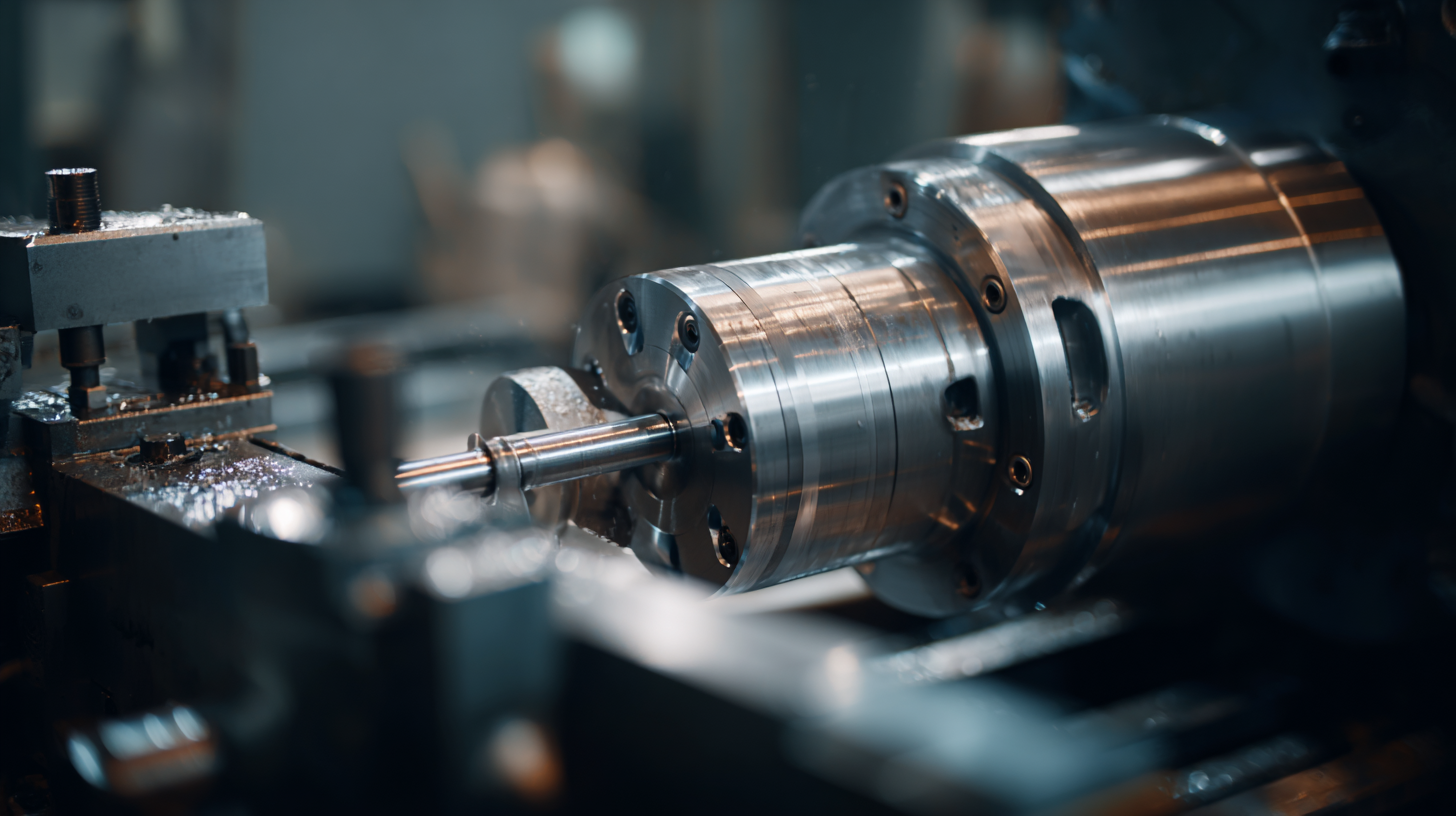

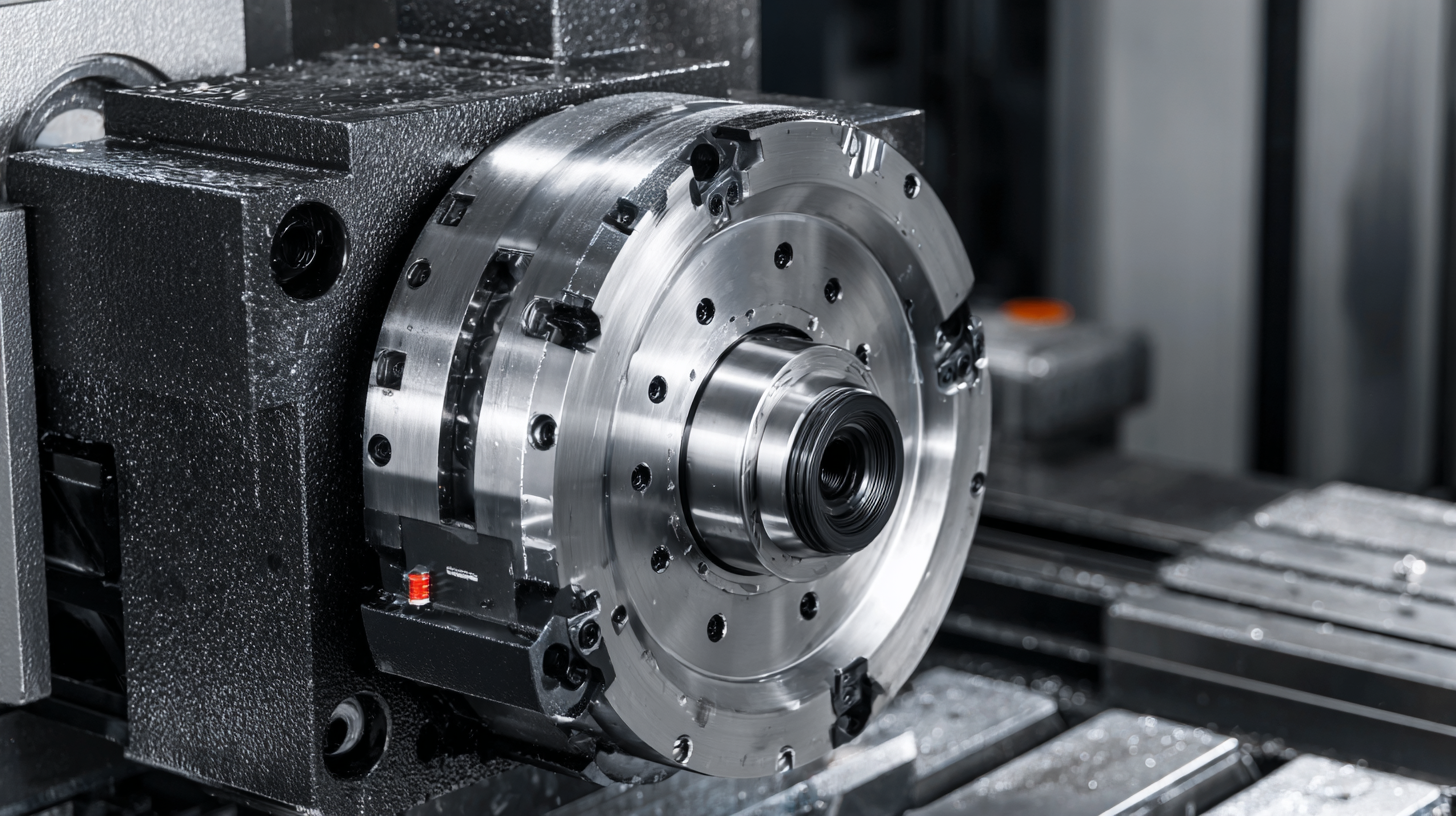

When selecting a horizontal milling machine for your business, it's essential to understand the key features that will align with your operational needs. Horizontal milling machines are known for their ability to handle complex tasks with high precision, making them indispensable in modern manufacturing environments. One of the most critical features to consider is the machine's spindle power, which directly influences cutting speed and the ability to work with various materials. A robust spindle ensures efficient operations and reduces downtime, ultimately enhancing productivity.

Another vital aspect is the machine's versatility, which can be significantly improved by its compatibility with advanced CNC technology. CNC milling machines equipped with multiple axes allow for intricate designs and shapes to be produced with ease. As the market expands, particularly with a projected growth rate of 9.9%, it's crucial to choose a machine that supports the latest advancements, such as AI integrations that improve not only precision but also operational efficiencies. Understanding these features will help businesses make informed decisions, ensuring they invest in a horizontal milling machine that meets both current and future demands.

When selecting the best horizontal milling machine for your business, a thorough evaluation of your specific needs is crucial. Understanding your production volume, the types of materials you'll be working with, and the complexity of your projects will guide your decision-making process. According to a recent report by MarketsandMarkets, the global CNC machine market is expected to grow from $63.2 billion in 2020 to $100.5 billion by 2026, indicating a rising demand for advanced machinery that can meet diverse business requirements.

Consider the precision and versatility that a horizontal milling machine offers. For instance, businesses that require continuous and efficient operations often benefit from machines with higher spindle speeds and improved torque, enhancing productivity. The manufacturing sector's emphasis on reducing cycle times is evident, as noted in a study by Grand View Research, which highlights that effective machinery can increase operational efficiency by up to 30%. Thus, assessing features such as tool changing capabilities, size limits, and the machine's overall adaptability will ensure you make an informed investment that aligns with future business growth.

When choosing the best horizontal milling machine for your business, it is essential to analyze and compare leading brands and models available in the market. Each brand offers unique features tailored to different industrial needs, making it critical to understand which machine can best enhance your productivity. Evaluating factors such as precision, versatility, and cost-effectiveness will guide your decision, ensuring that the machine aligns with your specific operational requirements.

The competition among brands is fierce, much like the automotive industry where various manufacturers vie for dominance. Recent trends emphasize the importance of innovation and efficiency, traits that also apply to milling machine manufacturers.

By examining the performance metrics and feedback from existing users, businesses can make informed decisions. Overall, a thorough comparison of capabilities and brand reputations will lead you to the ideal horizontal milling machine that supports your business’s growth and efficiency.

When budgeting for a horizontal milling machine, it's essential to understand the total cost of ownership, which includes not only the initial purchase price but also operational costs, maintenance, and potential financing options. According to a report by the Association for Manufacturing Technology (AMT), businesses can expect to spend anywhere from $30,000 to well over $100,000 for high-quality horizontal milling machines, depending on the features and capabilities required. This significant investment necessitates a well-thought-out financial plan.

Financing options are crucial for many businesses, especially small to mid-sized companies that may need additional support to acquire such equipment. A survey by the National Federation of Independent Business (NFIB) found that nearly 70% of small business owners rely on financing to purchase machinery. Leasing, loans, and equipment financing are common strategies. It’s important to evaluate the total cost of financing, including interest rates and terms, which can vary significantly. By carefully assessing these aspects, businesses can make more informed decisions that align with their long-term financial health and operational goals.

When selecting a horizontal milling machine, maintenance and support considerations play a crucial role in ensuring long-term operational success. According to a report by the Association for Manufacturing Technology (AMT), regular maintenance can extend the life of a milling machine by up to 50%. This underscores the importance of establishing a proactive maintenance strategy that includes regular check-ups, timely repairs, and the use of quality replacement parts. Additionally, manufacturers with robust support systems often report up to 30% fewer unplanned downtimes, which can significantly impact productivity and profitability.

Moreover, businesses need to assess the availability of technical support and training from the machine provider. A study from the National Association of Manufacturers (NAM) indicates that organizations with comprehensive training programs for their operators experience a 25% increase in machine utilization. This highlights the value of investing not just in the milling machines themselves but also in the ongoing education and support for the workforce. By prioritizing these aspects, companies can ensure they maximize the return on investment in their horizontal milling machines while minimizing disruptions to their production processes.

5107 County Road C

Manitowoc, WI 54220

920-726-4526