920-726-4526

In today's fast-paced manufacturing landscape, efficiency and precision are paramount, making "Quick Turn CNC Machining" a crucial component for businesses looking to maintain a competitive edge. As industries evolve and customer demands shift, the need for rapid prototyping and swift production timelines becomes increasingly important. This blog will delve into the advantages of Quick Turn CNC Machining, examining how this technology can streamline your manufacturing processes, reduce lead times, and improve overall product quality. By understanding the key factors in selecting the right Quick Turn CNC Machining services, manufacturers can effectively meet their operational needs while also maximizing cost-effectiveness. Whether you're a seasoned manufacturer or just starting out, navigating the complexities of this machining method can unlock new opportunities for innovation and growth in your projects.

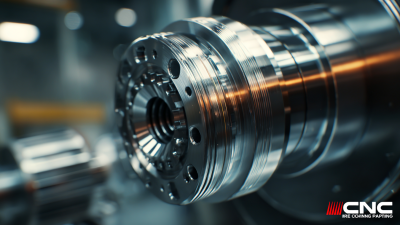

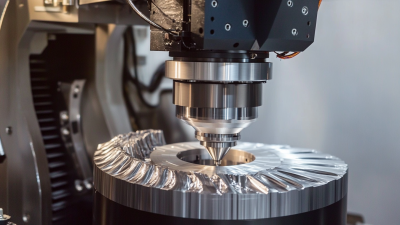

Quick turn CNC machining has emerged as a game-changer for manufacturers seeking speed and precision in their production processes. This technology encompasses advanced computer-controlled machinery that can rapidly produce high-quality components. One of the key features of quick turn CNC machining is its ability to handle complex geometries, which traditional manufacturing methods may struggle with. This capability is vital for industries that demand intricate designs with tight tolerances, making CNC machining the preferred choice.

Another significant advantage is the reduced lead time. Quick turn CNC services allow for expedited production schedules without sacrificing accuracy. This efficiency is particularly beneficial for businesses needing prototypes or small production runs urgently. By leveraging rapid prototyping and iterative design processes, manufacturers can swiftly go from concept to finished product, enabling them to be more responsive to market demands. Consequently, quick turn CNC machining not only enhances production efficiency but also fosters innovation by allowing manufacturers to experiment and refine their designs in real-time.

When considering quick turn CNC machining, it's essential to start by accurately assessing your manufacturing needs. According to a report by the Association for Manufacturing Technology (AMT), nearly 60% of manufacturers prioritize speed and flexibility in their production processes. Quick turn solutions can significantly reduce lead times, often delivering prototypes and small batches in as little as a week. This is particularly beneficial in industries like aerospace and automotive, where regulatory compliance requires rapid iteration and testing of designs.

In addition, the choice of materials can greatly influence the effectiveness of quick turn CNC machining. A study by the Society of Manufacturing Engineers (SME) indicates that 70% of engineers report challenges related to material selection in fast-paced production environments. Understanding the properties of materials—such as aluminum for lightweight structures or high-strength steels for heavy-duty applications—can ensure your manufacturing process is both efficient and cost-effective. This assessment not only aids in selecting the right machining partner but also in aligning with your project timelines and quality standards.

When selecting a quick turn CNC machining provider, there are several key factors to consider. First and foremost, assess the provider’s capabilities and expertise. Look for a company that specializes in the materials and processes relevant to your project. Understanding the range of services offered, such as milling, turning, or multi-axis machining, can ensure that the provider can meet your specific manufacturing needs effectively.

Additionally, turnaround time is a critical element in the decision-making process. Evaluate the provider's commitment to quick production cycles without sacrificing quality. It's also advisable to inquire about their quality control measures—certifications and standards can indicate a provider’s dedication to maintaining high-quality output. Lastly, consider customer service and communication, as a responsive provider can significantly enhance your overall experience and help address any potential issues swiftly. By carefully weighing these factors, you can select a quick turn CNC machining provider that aligns perfectly with your manufacturing requirements.

| Factor | Description | Importance Level | Average Turnaround Time |

|---|---|---|---|

| Material Options | Availability of various metals and plastics based on project needs. | High | 2-5 days |

| Technology Used | Modern CNC machines and software that enhance precision and efficiency. | High | 3-7 days |

| Quality Control | Processes and certifications ensuring product quality meets standards. | Critical | Varies |

| Cost Efficiency | Analysis of pricing versus quality and speed of service. | Medium | N/A |

| Customer Support | Availability of support for project changes and logistics. | High | Ongoing |

| Production Capacity | Ability to handle varying volumes, from prototypes to large runs. | Medium | 2-10 days |

When selecting a manufacturing method, cost is a crucial factor that can significantly influence your decision. Quick turn CNC machining, known for its rapid production capabilities, often presents an attractive alternative to traditional methods. While traditional machining processes may have lower upfront operational costs, they frequently involve longer lead times and labor-intensive setups. These factors can lead to increased overall expenses, especially for projects requiring swift turnaround and flexibility in design changes.

On the other hand, quick turn CNC machining, although potentially higher in initial expenditure, offers substantial long-term savings. The automation and precision of CNC machines reduce material waste and minimize the need for extensive manual labor, which translates to lower production costs over time. Moreover, the ability to quickly iterate on designs and produce prototypes can accelerate product development cycles, enabling businesses to bring products to market faster and reduce the risk of costly delays. By weighing the immediate costs against the potential for efficiency and faster delivery, companies can make informed decisions that align with their manufacturing needs and budget constraints.

Quick turn CNC machining has become an invaluable asset across various industries, significantly enhancing manufacturing efficiency and precision. According to a report by Grand View Research, the global CNC machining market size was valued at $63.5 billion in 2022, with a projected compound annual growth rate (CAGR) of 5.6% from 2023 to 2030. This growth is largely driven by industries such as aerospace, automotive, and medical devices, where rapid prototyping and high precision are crucial.

In the aerospace sector, quick turn CNC machining facilitates the production of complex components that require stringent quality standards. The demand for lightweight and durable parts has surged, with a Statista report predicting that the aerospace manufacturing sector will reach over $870 billion by 2026. Similarly, in the automotive industry, the need for rapid development of prototypes to keep up with consumer trends drives the adoption of quick turn CNC machining. According to a 2021 report from the Automotive Industry Association, 57% of automotive companies acknowledged improved time-to-market capabilities through advanced machining processes. Additionally, the medical device industry, valued at over $400 billion, relies on precision machining for the production of custom implants and instruments, underscoring the integral role of quick turn CNC machining in meeting strict safety and quality regulations.

5107 County Road C

Manitowoc, WI 54220

920-726-4526