920-726-4526

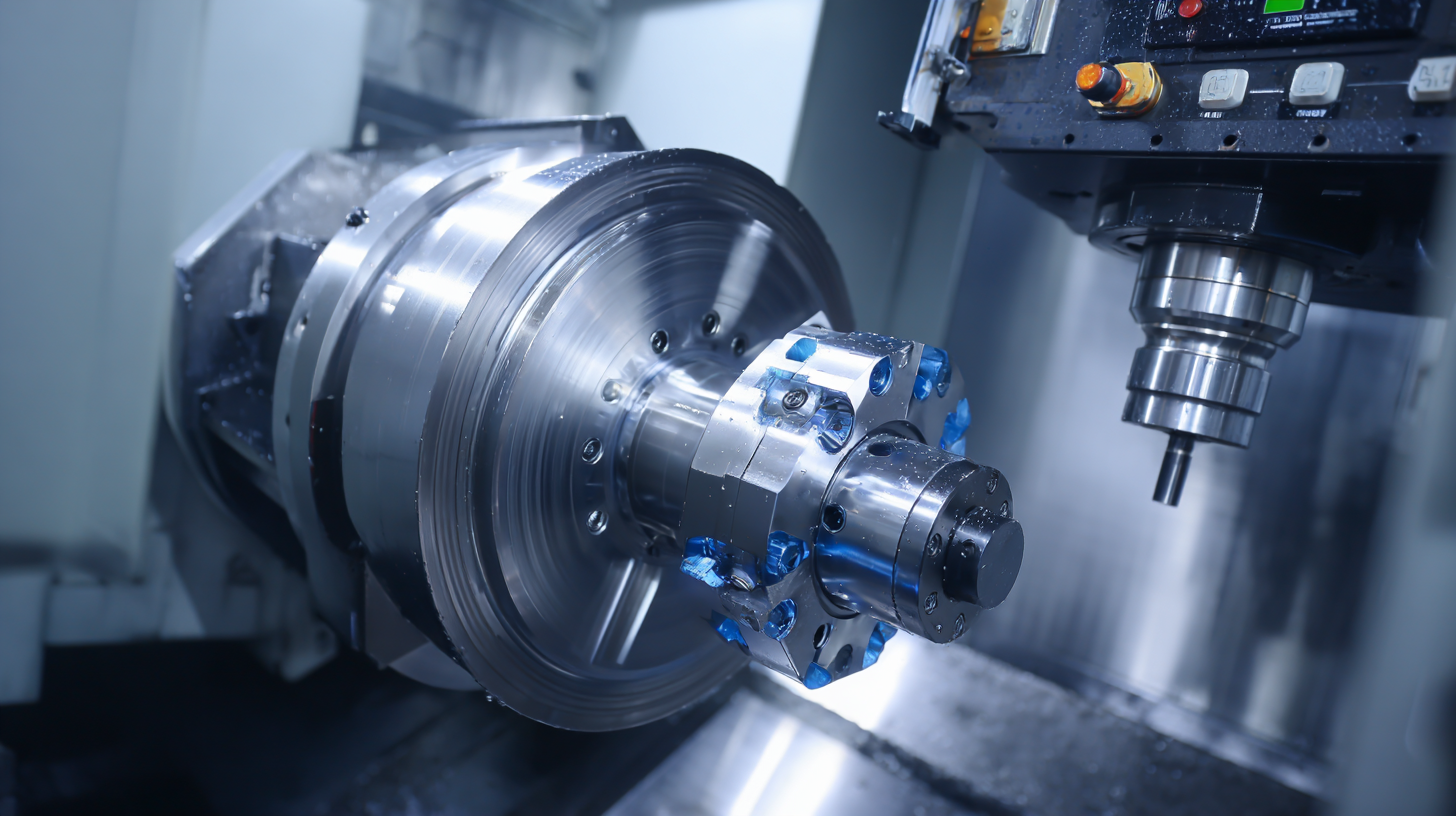

In the realm of precision manufacturing, China's advancements in 5 Axis CNC machines are setting new industry production standards and capturing significant shares in global markets. According to a recent report by MarketsandMarkets, the global CNC machine market is projected to reach USD 100 billion by 2025, growing at a CAGR of 6.5%. This growth is largely driven by the adoption of advanced machining techniques, particularly the 5 Axis CNC technology, which enhances operational efficiency and accuracy by allowing complex geometries to be machined in a single setup.

Notably, China has emerged as a formidable force in this sector, with its manufacturers investing heavily in innovation and quality control. This surge in technological prowess not only elevates product quality but also positions China at the forefront of the global CNC market, challenging traditional leaders and reshaping industry dynamics.

When considering the top-notch CNC machine suppliers in China, it's crucial to identify key factors that distinguish the best from the rest. The quality of machinery plays a significant role, as manufacturers seek to elevate their production standards. Suppliers that prioritize innovation and precision in their 5-axis CNC machines are more likely to gain a competitive edge in the global market. By evaluating technical specifications and machine capabilities, businesses can ensure they select equipment that meets their operational needs.

Additionally, understanding the supplier's position within the broader machine tools market can provide valuable insights. The industry is projected to experience substantial growth, with expectations of reaching $196 billion by 2034. Suppliers that align with this growth trajectory often invest in research and development, enabling them to offer state-of-the-art solutions. It's essential to assess the manufacturer's commitment to quality assurance and their ability to adapt to emerging technologies, such as additive manufacturing, which can significantly impact production efficiency. By considering these crucial elements, manufacturers can make informed decisions and select suppliers that will support their long-term success in a competitive environment.

When searching for a reliable CNC machine manufacturer, it is essential to consider several key qualities that can significantly impact both production efficiency and product quality. One of the foremost attributes to look for is experience in the industry. Manufacturers with a proven track record are more likely to understand the challenges and intricacies of CNC machining, which translates to superior craftsmanship and innovative solutions tailored to customers' needs. Additionally, a well-established manufacturer often possesses the latest technology and machinery necessary for producing high-precision 5-axis CNC machines.

Another critical factor is after-sales support. A reputable CNC machine manufacturer should provide comprehensive service agreements that include installation, training, and ongoing maintenance. This ensures that clients can maximize their investment by maintaining optimal performance and minimizing downtime. Furthermore, transparency in communication and a willingness to customize machines based on specific applications can indicate a manufacturer's commitment to customer satisfaction and product excellence. By focusing on these essential qualities, businesses can forge partnerships with manufacturers that not only meet but exceed their expectations in the competitive global market.

When sourcing CNC machines, especially 5-axis models from China, quality assurance becomes paramount. Crafting a comprehensive supplier checklist can significantly elevate your procurement process.

Start by evaluating the supplier's certifications and standards, such as ISO 9001 or CE marking. These certifications indicate adherence to international quality management principles and ensure that the machines produced meet stringent safety and performance benchmarks.

Next, consider the supplier's reputation within the industry. Conduct thorough research by checking customer testimonials, reviews, and case studies. Engaging with current users of the supplier’s machines can provide invaluable insights into performance reliability and maintenance support.

Moreover, assess the supplier’s technical capabilities, including their experience with advanced technologies and innovation in CNC machining, to ensure you are selecting a partner that can keep pace with evolving market demands.

Additionally, don't overlook the importance of post-sale support and the availability of spare parts. A reliable supplier will offer comprehensive after-sales services, including training for your staff and prompt technical support. This level of commitment not only ensures operational efficiency but also fosters a long-term partnership that can drive your business growth in the competitive global CNC marketplace.

In the rapidly evolving landscape of manufacturing, the importance of evaluating supplier credentials cannot be overstated, particularly for sectors such as CNC machining. A diligent assessment of certifications and industry experience is pivotal for ensuring product quality and compliance with global standards. According to a recent report from a leading research firm, industries that utilize certified suppliers experience a 30% reduction in production defects, significantly enhancing overall efficiency.

Moreover, as China continues to assert its dominance in the global market for five-axis CNC machines, understanding supplier capabilities becomes crucial. The prevalence of rigorous certification processes, such as ISO9001, equips manufacturers with the assurance of reliable production methodologies. In fact, companies adhering to such quality management systems report a 20% increase in customer satisfaction and retention. This trend not only reflects a commitment to excellence but also positions Chinese manufacturers favorably in international markets, where quality assurance is a prerequisite for success.

| Supplier Type | Certification | Industry Experience (Years) | Key Features | Market Regions |

|---|---|---|---|---|

| Manufacturer | ISO 9001, CE | 15 | High Precision, Automation | Asia, Europe, North America |

| Distributor | ISO 14001, RoHS | 10 | Customer Support, Custom Solutions | Europe, Australia |

| Service Provider | ISO 45001 | 12 | Maintenance, Training | Global |

| OEM Partner | TS16949, AS9100 | 20 | High Volume Production | Asia, North America |

| Research Institution | None | 25 | Innovative Solutions, R&D | Asia, Europe |

Effective communication is essential for companies engaging with suppliers, especially in the competitive landscape of the CNC machine industry. As businesses strive to enhance their operational efficiency and product quality, establishing robust communication strategies can significantly influence their success. Regular and transparent interactions not only help in understanding supplier capabilities but also foster trust, leading to better collaboration and innovation. By prioritizing open dialogue, companies can address concerns promptly and adapt to changes in demand or market conditions.

Moreover, with the retail season approaching, the importance of multilingual communication becomes even more pronounced. As brands look to expand their reach into global markets, leveraging advanced AI translation tools can facilitate a smoother exchange of information. This enables businesses to engage with suppliers and customers alike across diverse regions, ensuring that marketing strategies are effectively tailored to local preferences. By embracing these technologies, companies can not only improve their supplier relationships but also capitalize on opportunities during peak sales periods, ultimately driving growth and competitiveness in the global arena.

5107 County Road C

Manitowoc, WI 54220

920-726-4526