920-726-4526

In the rapidly evolving landscape of global manufacturing, the CNC turning machine stands out as a pivotal tool driving precision and efficiency. According to a recent report by MarketsandMarkets, the global CNC machine market is projected to reach $100.9 billion by 2026, growing at a CAGR of 6.4% from 2021 to 2026. This surge is largely attributed to the increasing demand for customized components across various industries, including automotive, aerospace, and medical devices. However, manufacturers face significant challenges in optimizing their CNC turning operations, such as high initial costs, technological integration, and skill shortages. Addressing these issues is crucial for companies aiming to leverage the full potential of CNC turning machines and maintain competitive advantages in a market characterized by rapid technological advancements and ever-changing customer needs.

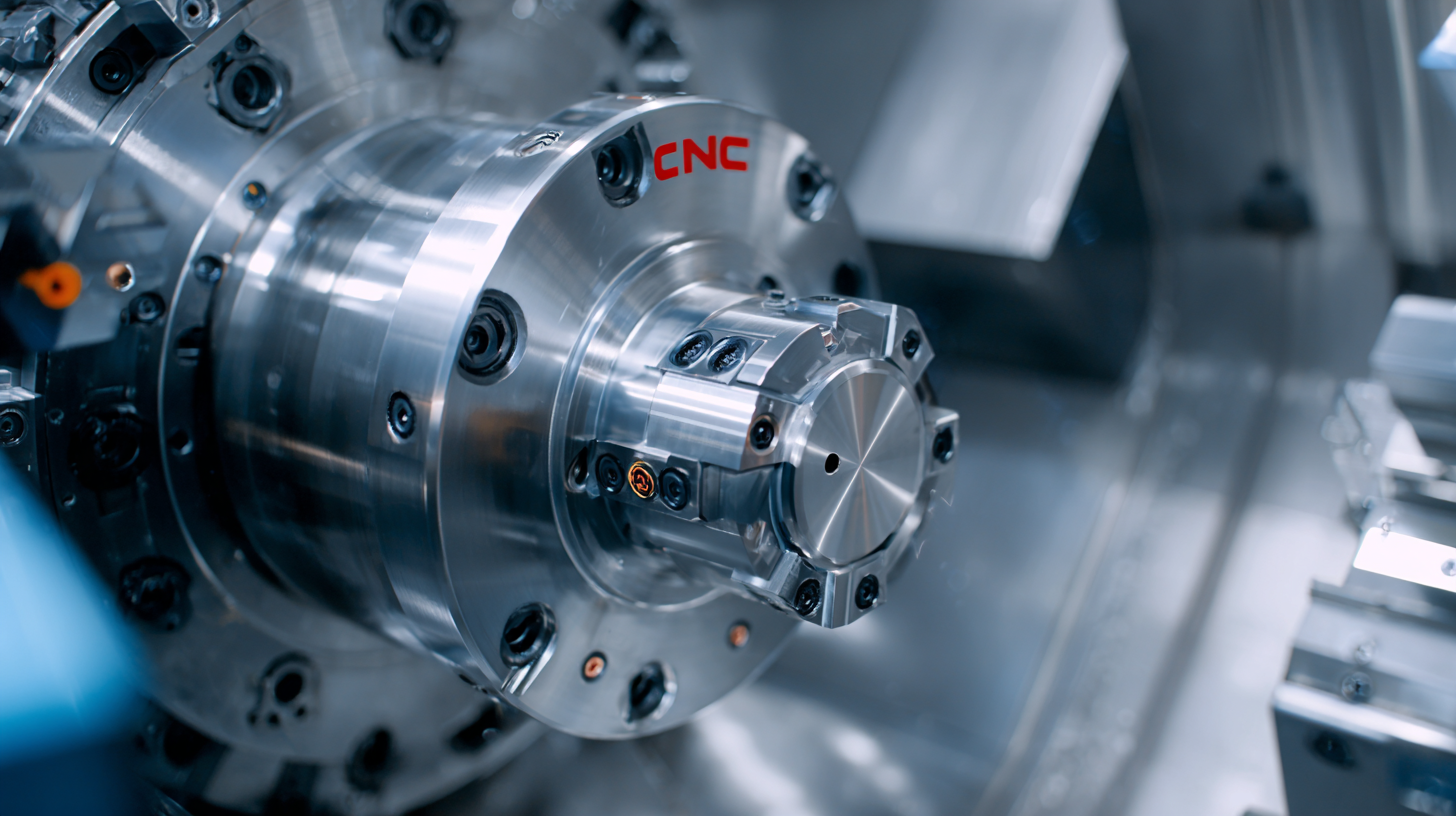

When exploring CNC turning machines, it's essential to understand the various types available and their specifications. CNC (Computer Numerical Control) turning machines can be broadly categorized into manual lathes, CNC lathes, and multi-axis lathes. Manual lathes require operator input for adjustments, making them less suited for high-volume production. In contrast, CNC lathes streamline the manufacturing process by automating tool movements, resulting in enhanced precision and efficiency. Their programming capabilities allow manufacturers to produce intricate designs with greater consistency and minimal human error.

The capabilities of CNC turning machines vary according to their classifications. For instance, basic CNC lathes are ideal for simple shapes, while advanced multi-axis lathes integrate additional axes for more complex machining operations. These machines can perform operations such as drilling, milling, and threading all in one setup, which significantly reduces production time. Understanding the specifications—such as maximum diameter, length of cut, and spindle speed—is crucial for manufacturers to select the right machine, ensuring it aligns with their production needs and operational goals. By thoroughly evaluating these aspects, companies can optimize their machining processes and enhance overall productivity.

In the realm of global manufacturing, CNC turning machines play a pivotal role across various sectors, each facing unique challenges. Industries such as aerospace, automotive, and medical manufacturing employ these machines for precision and efficiency, yet they must navigate diverse operational hurdles.

For example, the aerospace sector demands extremely tight tolerances and rigorous quality standards, which necessitate advanced CNC turning technologies that can ensure repeated accuracy. Furthermore, compliance with stringent regulations adds an additional layer of complexity for manufacturers in this field.

Conversely, the automotive industry experiences rapid production cycles that require flexibility and scalability from CNC turning machines. Balancing the need for swift output with the demand for high-quality components creates a distinctive set of challenges. In contrast, the medical manufacturing sector prioritizes biocompatibility and the customization of parts, necessitating versatile CNC turning solutions that can cater to a range of specifications.

Each sector's unique requirements highlight the importance of a comparative analysis of CNC turning machines, enabling manufacturers to select appropriate technologies that align with their specific operational demands while addressing industry-specific challenges.

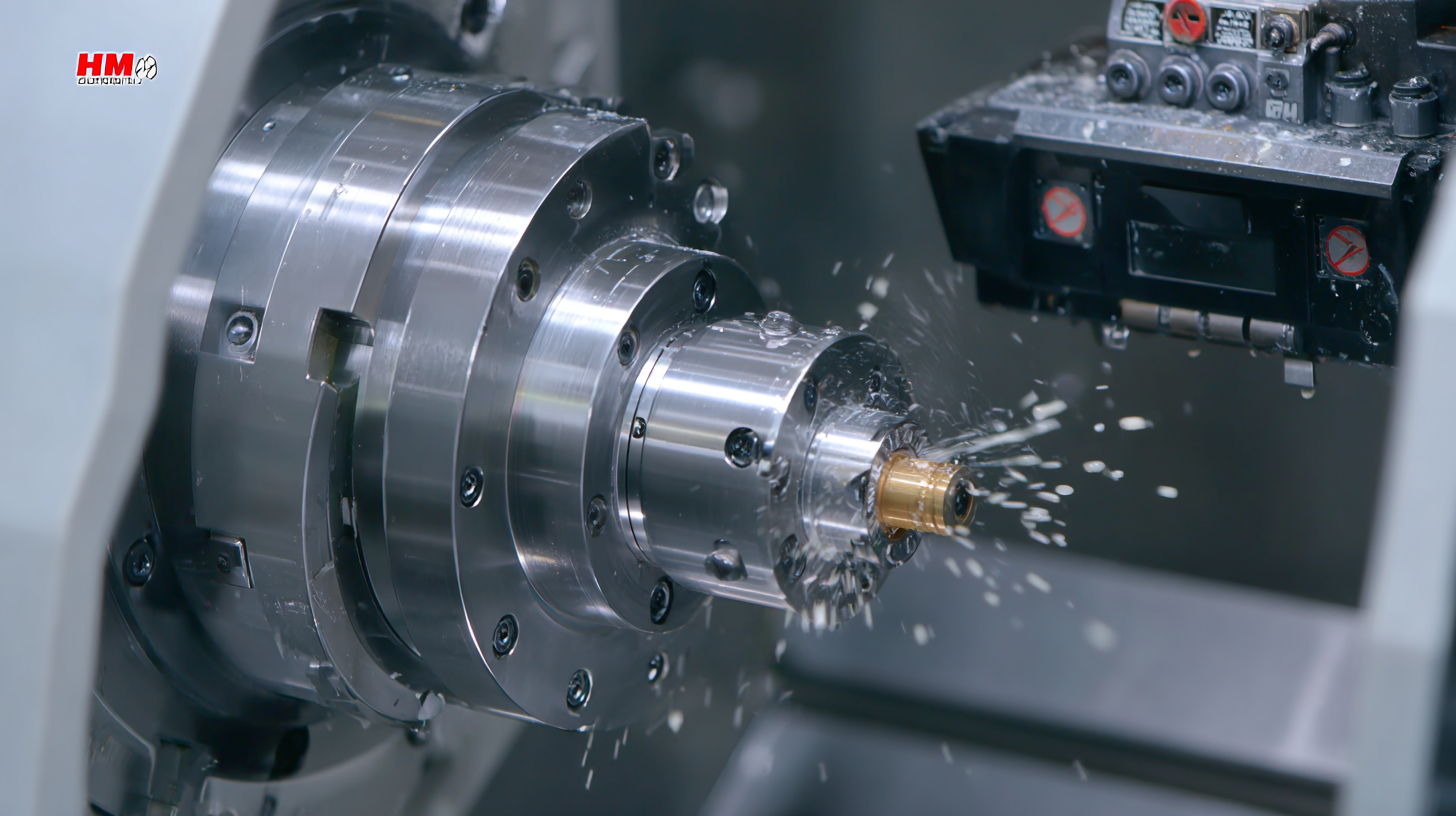

When it comes to the performance and productivity of CNC turning machines, the choice of materials plays a pivotal role. Industry reports indicate that selecting the right material can enhance machining efficiency by up to 30%, significantly reducing cycle times. Materials such as aluminum and high-strength alloys often yield better results due to their machinability and reduced tool wear, which is crucial for maintaining optimal operating conditions and minimizing downtime.

Tips: Always assess material properties before machining. Understanding thermal conductivity and hardness can help in selecting appropriate cutting tools and speeds, thereby improving overall productivity.

Moreover, advanced CNC turning technologies now allow for better adaptability to various materials. A recent survey highlighted that manufacturers utilizing adaptive machining methods had 15% higher output and could easily switch between different material types. This flexibility is increasingly essential in today's manufacturing landscape, where rapid prototyping and customized solutions are gaining traction.

Tips: Investing in training for operators on new materials and machinery technology can lead to significant gains in both performance and efficiency, ensuring that your facility stays competitive in a fast-evolving market.

| Material Type | Hardness (HV) | Machining Speed (m/min) | Tool Life (hours) | Surface Finish (Ra μm) |

|---|---|---|---|---|

| Aluminum Alloy | 70 | 300 | 60 | 0.8 |

| Stainless Steel | 200 | 100 | 30 | 1.5 |

| Brass | 120 | 250 | 50 | 0.6 |

| Carbon Steel | 150 | 120 | 40 | 1.0 |

The rapid evolution of global manufacturing demands that CNC turning machines adapt to a multitude of diverse product applications. However, adapting these machines poses several challenges for manufacturers who seek efficiency and precision. One of the primary challenges is the variety of materials used in different industries. Each material, from metals to plastics, has distinct mechanical properties that affect machining speeds, tool wear, and process parameters. Manufacturers must ensure that their CNC turning machines are versatile enough to handle these variations without sacrificing quality or increasing production time.

Furthermore, the complexity of modern designs adds another layer of difficulty. With the rise of custom and intricate part designs, CNC turning machines must be programmed to execute highly detailed specifications. This requires advanced software integration and skilled operators who can navigate the intricacies of programming and machine setup. Additionally, the need for real-time adjustments during production can strain existing processes, making it essential for manufacturers to train their workforce and invest in more sophisticated technologies to keep pace with these demands. This dynamic environment poses a significant challenge for adapting CNC turning machines effectively in a global marketplace.

The CNC turning technology landscape is undergoing a significant transformation driven by digitalisation, the Internet of Things (IoT), and artificial intelligence (AI). These advancements are reshaping production strategies across the globe, as manufacturers increasingly adopt high-precision, multi-axis machining centers to meet rising demands. The CNC machine tools market is projected to grow substantially, with estimates indicating an increase of $21.9 billion from 2025 to 2029, highlighting the critical role of AI in enhancing operational efficiency and precision.

Emerging trends indicate a growing reliance on automation and intelligent digital agents, expected to infiltrate numerous sectors by 2025. As businesses strive for more efficiency, the integration of AI and robotics in CNC machining processes enables manufacturers to achieve higher productivity and reduce human error. This not only aids in meeting the challenges of a competitive global market but also aligns with the increasing customer expectations for quality and speed in production. The ongoing evolution in CNC technology is a testament to the industry’s adaptability and forward-thinking approach in navigating the complexities of modern manufacturing.

5107 County Road C

Manitowoc, WI 54220

920-726-4526