920-726-4526

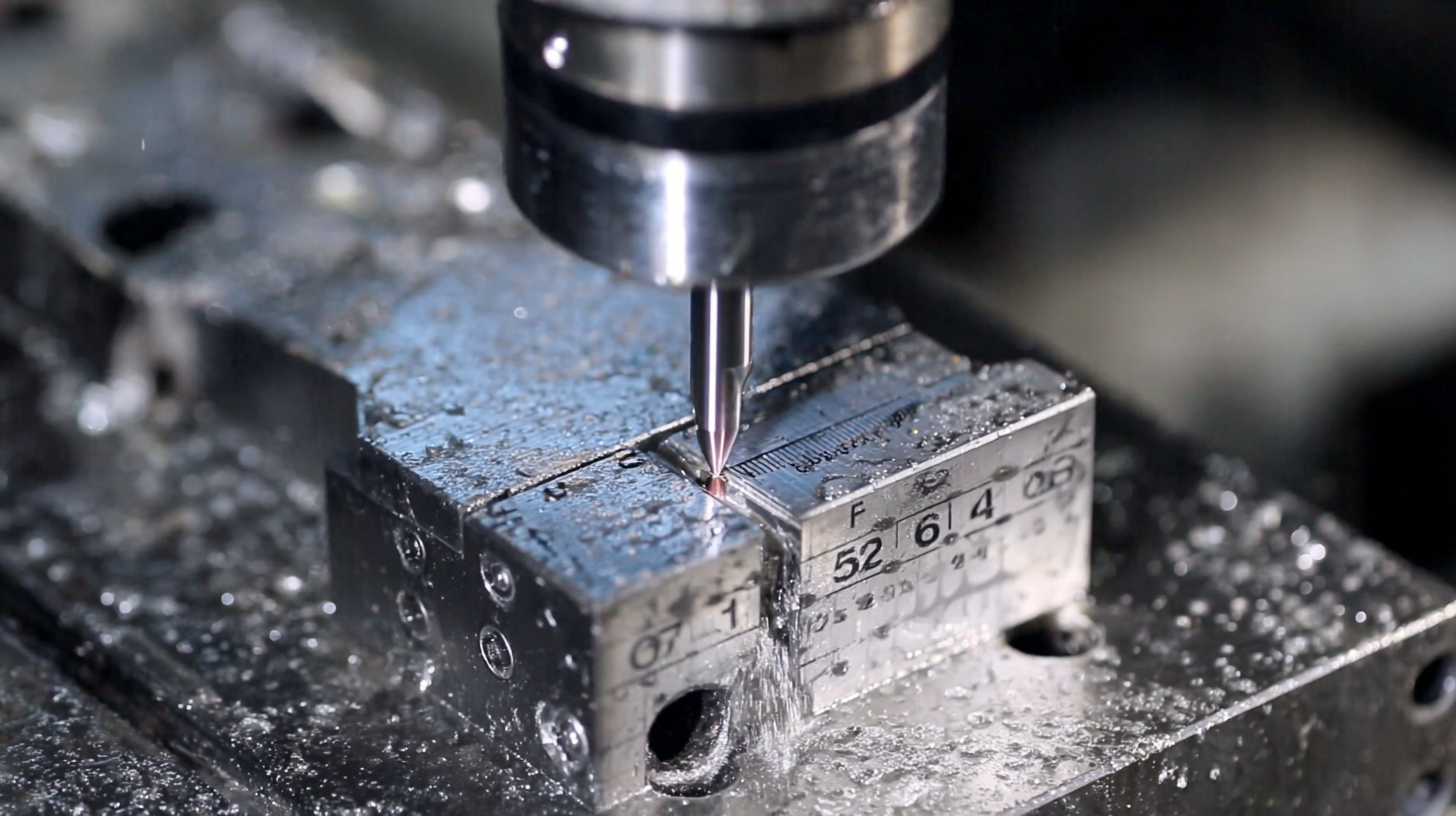

In the rapidly evolving landscape of manufacturing, achieving precision in custom CNC (Computer Numerical Control) machining has become increasingly critical. A recent report by Market Research Future indicates that the global CNC machining market is projected to reach approximately $100 billion by 2026, driven by rising demand for precision engineering across various industries such as aerospace, automotive, and medical devices. However, despite this growth, selecting a quality manufacturer remains a daunting challenge due to factors like varying machining capabilities, material availability, and technological expertise. Companies often grapple with the task of vetting potential partners to ensure they meet rigorous standards for accuracy and reliability while balancing cost and lead time. Therefore, understanding how to effectively choose a manufacturer that can deliver high-quality custom CNC solutions is essential for maintaining competitiveness in today’s precision-driven marketplace.

In 2023, the landscape of custom CNC precision machining presents a mix of technological advancements and persistent challenges. According to a report by the International Federation of Robotics, the adoption of advanced robotics in CNC machining has increased efficiency by 30%, allowing manufacturers to achieve tighter tolerances and higher precision levels. However, despite these advancements, achieving the ideal custom CNC precision remains complex, primarily due to the variability in material properties and the intricacies of programming.

Moreover, a survey conducted by the Precision Machined Products Association indicated that 65% of manufacturers reported difficulties in maintaining consistent precision across various production runs. Factors contributing to this issue include the skill level of operators, machine calibration, and the integration of CNC systems with CAD/CAM software. As the market demand for customized, high-tolerance components grows, companies are increasingly investing in training programs and advanced predictive maintenance solutions to address these precision challenges and enhance their operational capabilities.

The CNC precision industry is grappling with several key challenges that hinder its ability to achieve optimal custom machining outcomes. One significant issue is the growing complexity of designs that clients demand. According to a report by Statista, the global market for CNC machining is projected to reach $100 billion by 2025, driven by the aerospace and automotive sectors which are increasingly seeking intricate and lightweight components. This trend places immense pressure on manufacturers to adopt advanced technologies that can handle such intricate specifications while ensuring consistent quality.

Another challenge is the skill gap in the workforce. The National Institute for Metalworking Skills (NIMS) reports a shortage of qualified CNC machinists, with over 400,000 positions expected to remain unfilled by 2025. This lack of skilled labor not only impacts production efficiency but also the ability to maintain stringent precision standards. In addition, many CNC machines are still operating with legacy systems, making it difficult to integrate newer technologies like automation and real-time data analytics, which are critical for meeting the rising demands for precision and efficiency in the industry. As a result, addressing these challenges is essential for the CNC precision sector to fulfill its potential and remain competitive in a rapidly evolving market.

| Challenge | Description | Impact Level | Possible Solutions |

|---|---|---|---|

| Material Variability | Inconsistencies in raw materials can affect precision. | High | Quality control checks and supplier audits. |

| Machine Calibration | Regular calibration is needed for maintaining accuracy. | Medium | Scheduled maintenance and calibration protocols. |

| Operator Skill Level | Skilled operators are critical for precision work. | High | Training programs and certifications for operators. |

| Software Integration | Lack of integration leads to inefficiencies in design to manufacturing. | Medium | Invest in integrated software solutions. |

| Tool Wear and Tear | Worn tools can compromise the accuracy of cuts. | High | Regular tool inspections and timely replacements. |

| Environmental Factors | Temperature and humidity can affect machining processes. | Medium | Control environments and use of climate control systems. |

The future of CNC precision is predominantly influenced by technological advancements that are continuously reshaping the industry. As manufacturers strive for enhanced performance and durability, particularly in critical applications like automotive cylinder liners, the integration of cutting-edge technologies becomes essential. These advancements not only meet the rising demand driven by stricter environmental regulations but also enhance the efficiency of manufacturing processes.

To achieve optimal CNC precision, it’s important to focus on specific strategies. Firstly, investing in high-quality raw materials ensures that the end products withstand rigorous operational demands. Secondly, adopting advanced software solutions for simulation and modeling can significantly reduce errors during the manufacturing process. Lastly, continuous training for operators to utilize modern CNC machinery allows for improved precision and operational efficiency.

Furthermore, the exploration of emerging materials like PMMA in microfluidics indicates a notable shift towards innovative applications of CNC machining, suggesting that those in the industry must stay ahead by embracing both new technologies and materials. By aligning with these trends, manufacturers can enhance their competitive edge in the market.

The custom CNC market faces significant challenges driven by evolving market demand trends. As industries such as automotive, general machinery, precision engineering, and transportation machinery grow, the need for precise and efficient custom CNC operations intensifies. The projected growth from a valuation of approximately $13 billion in 2024 to $22 billion by 2033 showcases a compound annual growth rate of 6.1%. This shift is significantly influenced by advancements in technology and material processing, driving the demand for more specialized CNC machining solutions.

To navigate these challenges, companies can consider several strategies. One essential tip is to invest in the latest CNC technology and software, enabling operators to enhance precision and efficiency. Additionally, establishing close relationships with clients can provide valuable insights into their needs, allowing for more tailored solutions. Furthermore, integrating data analytics into operations can help identify trends and optimize production processes.

By focusing on these approaches, custom CNC businesses can not only meet current market demands but also position themselves for future growth. Emphasizing technological advancements and strong customer relations will be pivotal in achieving the best CNC precision in an increasingly competitive landscape.

Achieving best custom CNC precision is an ongoing challenge that many manufacturers grapple with as they integrate advanced technologies. By 2025, it is essential to develop strategic solutions that tackle the barriers to precision CNC machining. One major hurdle is the adoption of CNC automation, particularly the integration with robotic systems. According to recent reports, around 58% of manufacturers are hesitating to invest in CNC automation due to concerns regarding costs and the complexity of implementation. However, the advantages of such integration include faster tool changes and enhanced material handling efficiencies, which can significantly reduce operational downtime.

Moreover, the industry is projected to grow substantially, driven by the growing demand for precision parts across sectors like aerospace and automotive. In fact, precision machining is expected to reach a market value of approximately $3 billion by 2026. Emphasizing continual skill development and workforce training will be key in overcoming these hurdles. Research indicates that companies investing in human capital alongside technology upgrades are more likely to see improved precision outcomes and overall production efficiency. By prioritizing these strategic solutions, manufacturers can position themselves favorably in an increasingly competitive landscape.

5107 County Road C

Manitowoc, WI 54220

920-726-4526