920-726-4526

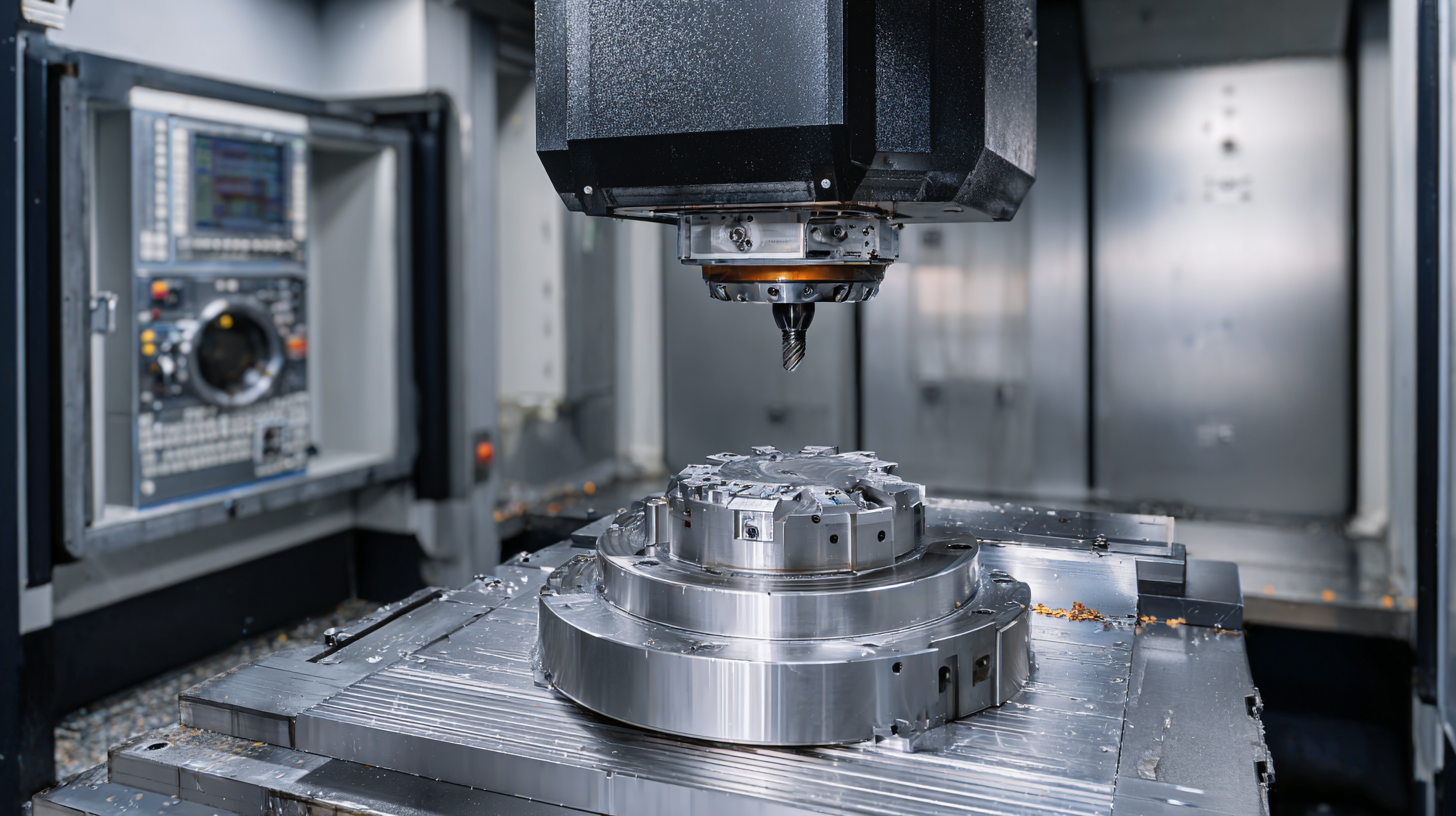

As the landscape of precision manufacturing evolves, the demand for advanced technologies to enhance productivity and accuracy is skyrocketing. Among these innovations, the 5 Axis CNC machine stands out as a pivotal tool that significantly boosts machining capabilities by allowing simultaneous movement along multiple axes.

According to a recent report by MarketsandMarkets, the global CNC machine market is projected to reach $117.2 billion by 2025, with a considerable share attributable to 5 Axis CNC machines, which are increasingly favored for their ability to create complex geometries and deliver superior surface finishes.

However, as industry needs diversify, manufacturers are exploring a variety of alternatives that can complement or even surpass the performance of traditional 5 Axis systems. This blog delves into these innovative technologies that are transforming the paradigm of precision manufacturing, ensuring that businesses remain competitive in a rapidly advancing market.

According to a recent report by MarketsandMarkets, the global CNC machine market is projected to reach $117.2 billion by 2025, with a considerable share attributable to 5 Axis CNC machines, which are increasingly favored for their ability to create complex geometries and deliver superior surface finishes.

However, as industry needs diversify, manufacturers are exploring a variety of alternatives that can complement or even surpass the performance of traditional 5 Axis systems. This blog delves into these innovative technologies that are transforming the paradigm of precision manufacturing, ensuring that businesses remain competitive in a rapidly advancing market.

As the manufacturing landscape evolves, industries are exploring innovative alternatives to traditional 5 Axis CNC machines. These alternatives are not just about maintaining precision but also enhancing speed and efficiency in production processes. Emerging technologies, such as advanced additive manufacturing and robotics, are playing a pivotal role in this transformation. By leveraging these advancements, manufacturers can achieve rapid prototyping without compromising on quality, thereby reducing lead times and meeting the demands of a fast-paced market.

Additionally, the integration of artificial intelligence and blockchain technology into manufacturing processes is revolutionizing how products are designed and produced. These technologies facilitate smarter supply chain management and enable real-time tracking of materials, fostering a more sustainable circular economy. As companies continuously seek to optimize their operations, exploring these top alternatives to 5 Axis CNC machines is crucial for remaining competitive in today's dynamic manufacturing environment.

| Technology | Key Features | Advantages | Typical Applications |

|---|---|---|---|

| Robotics Integration | Automated systems for precise movements | Increased efficiency and reduced labor cost | Assembly, welding, and painting |

| Laser Cutting Machines | High-precision cutting with laser technology | Clean edges and minimal material waste | Sheet metal fabrication, engraving |

| Waterjet Cutting Machines | Cutting with high-pressure water streams | Versatile for different materials, no heat affected zone | Glass, stone, and metal cutting |

| EDM (Electrical Discharge Machining) | Precision machining using electrical discharges | High precision in hard materials | Mold making, tool and die manufacturing |

| Hybrid Manufacturing Systems | Combination of additive and subtractive processes | Flexibility in production and material utilization | Aerospace, medical implants |

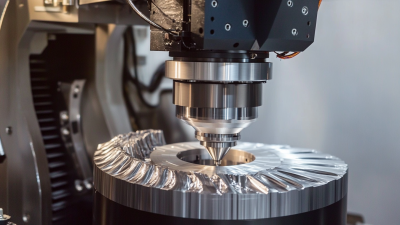

In the rapidly evolving landscape of precision manufacturing,

hybrid manufacturing is emerging as a revolutionary approach

that integrates traditional machining techniques with advanced additive processes. This innovative fusion

allows for the creation of complex geometries and intricate designs that are often unattainable

with conventional methods alone. By leveraging the strengths of both subtractive and additive manufacturing,

hybrid systems can produce high-quality parts more efficiently,

reducing material waste and production time significantly.

In the rapidly evolving landscape of precision manufacturing,

hybrid manufacturing is emerging as a revolutionary approach

that integrates traditional machining techniques with advanced additive processes. This innovative fusion

allows for the creation of complex geometries and intricate designs that are often unattainable

with conventional methods alone. By leveraging the strengths of both subtractive and additive manufacturing,

hybrid systems can produce high-quality parts more efficiently,

reducing material waste and production time significantly.

The real game changer lies in the flexibility these hybrid CNC machines offer. Operators can seamlessly

switch between milling and 3D printing functions

within a single setup, paving the way for more streamlined

production workflows. This capability not only enhances productivity

but also allows manufacturers to respond swiftly to varying market demands and customized orders. As

industries seek to improve their competitive edge, the adoption of hybrid manufacturing technologies is becoming

essential, showcasing how innovation continues to transform the realm of CNC machining.

Robotic automation is revolutionizing precision manufacturing, enhancing efficiency and productivity across various industries. According to a report by the International Federation of Robotics (IFR), the global market for industrial robots is expected to reach $25 billion by 2025, with an annual growth rate of 12%. This surge in adoption is driven by the need for manufacturers to increase output while maintaining precision, especially in high-stakes sectors like aerospace and automotive.

The integration of robotic systems in CNC machining processes has led to significant improvements in cycle times and accuracy. For instance, a study by Deloitte Insights revealed that companies implementing robotic automation could see a 30-50% reduction in manufacturing errors. This automation not only streamlines operations but also allows for real-time monitoring and adjustments, ensuring that machines operate at optimal levels throughout the production process. As technology advances, the collaboration between robotics and CNC machining is set to redefine the landscape of precision manufacturing, making it more agile and cost-effective.

Additive manufacturing, often referred to as 3D printing, is increasingly recognized as a crucial complement to traditional CNC machining, especially in the context of precision manufacturing. According to a report by Wohlers Associates, the global additive manufacturing market is expected to reach over $35 billion by 2024, indicating a significant shift towards technologies that can address limitations inherent in CNC processes. This innovation is particularly vital for industries that demand complex geometries and rapid prototyping, facilitating a more agile manufacturing environment.

One of the primary advantages of additive manufacturing is its ability to create parts with intricate designs that are not feasible with traditional subtractive methods. For instance, companies like Airbus have reported substantial weight savings by using 3D-printed components in their aircraft production, with some 3D-printed parts weighing 55% less than their conventional counterparts. This synergy between additive and subtractive processes is bridging gaps in CNC capabilities, enabling manufacturers to not only produce more complex components but also to optimize performance and reduce material waste, further enhancing sustainability in the manufacturing sector.

Digital Twin Technology is revolutionizing the landscape of CNC operations by enhancing accuracy and enabling predictive maintenance. This innovative technology creates a virtual replica of physical assets, allowing manufacturers to simulate, predict, and optimize their operations in real time. According to a report by Gartner, by 2025, 75% of organizations will implement digital twin technology, underscoring its critical role in reducing downtime and improving precision. This predictive capability helps in identifying potential issues before they lead to costly failures, ensuring that CNC machines operate at their peak efficiency.

When integrating digital twin technology, consider the following tips: First, ensure that your data collection processes are robust. Accurate data is crucial for effective simulations and predictions. Second, involve your team in the digital twin implementation process; their insights can drive successful integration and utilization. Lastly, regularly update and validate your digital twin to reflect changes in the physical environment and operations to maintain its relevance and accuracy.

The benefits of utilizing digital twin technology are vast. A study from McKinsey suggests that companies leveraging this technology can see a reduction in maintenance costs by up to 30% and an increase in operational efficiency by up to 20%. As CNC operations continue to adopt this innovative solution, businesses can stay ahead of the competition while improving their manufacturing processes.

5107 County Road C

Manitowoc, WI 54220

920-726-4526